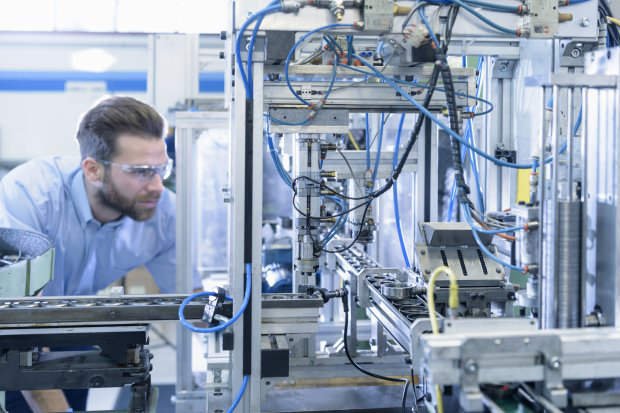

Understanding the Silent Killer in Industrial Automation

Heat is an insidious enemy in industrial automation. It quietly degrades critical components. High temperatures directly shorten the lifespan of Variable Frequency Drives (VFDs) and Programmable Logic Controllers (PLCs). Therefore, ignoring thermal management guarantees future failures. Engineers must prioritize effective cooling solutions now. This proactive approach saves significant repair costs later. High ambient temperatures severely challenge control systems.

The Critical Impact on PLCs and DCS Modules

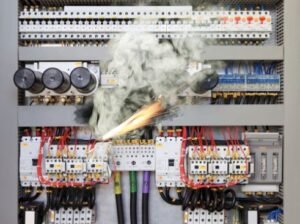

PLCs (Programmable Logic Controllers) are the brains of factory automation. Distributed Control Systems (DCS) also rely on sensitive electronics. Excessive heat accelerates component aging within these modules. Moreover, heat can introduce subtle data corruption errors. These errors compromise system reliability and safety. Proper enclosure cooling is not optional; it is mandatory. For instance, reputable manufacturers like Siemens and Rockwell Automation specify strict operating temperature limits. Ignoring these limits voids warranties and risks catastrophic downtime.

VFDs and Motor Drives: Thermal Stress Points

Variable Frequency Drives (VFDs), or motor drives, generate considerable heat themselves. They handle high currents to control motor speed. Internal power semiconductors (IGBTs) are especially susceptible to thermal stress. As a result, overheating drastically reduces IGBT life. Frequent thermal cycling also weakens solder joints. This eventually leads to intermittent faults and complete drive failure. Effective dissipation of this internal heat is vital for drive longevity. Manufacturers must design for robust thermal management.

Experience and Expertise: The Cost of Component Degradation

My field experience confirms heat damage is slow but inevitable. We often see technicians replacing components prematurely. They replace them not due to electrical fault, but due to thermal fatigue. Overheated capacitors bulge and fail. Control boards become brittle and cracked. In addition, dust buildup often exacerbates the heat problem. This creates a vicious cycle of rising temperatures and accelerating failure rates. Preventing this requires regular inspection and cleaning protocols. Maintaining lower operating temperatures maximizes the system Mean Time Between Failures (MTBF).

Selecting the Right Enclosure Cooling Solution

Implementing effective cooling is the only defense against thermal death. Choosing the right method depends on the environment. Air conditioners offer precise temperature and humidity control. However, they require maintenance and consume energy. Filtered fan systems are simpler but only work when the ambient air is clean and cooler. For extreme or dirty environments, advanced liquid cooling or specialized heat exchangers are better options. Companies must budget for robust thermal solutions within their industrial automation projects. This investment ensures long-term operational success.

Author’s Viewpoint: A Proactive Shift in Maintenance

Many companies still adopt a reactive maintenance strategy. They only fix equipment after it fails. This approach is costly and inefficient in the modern era. I believe a shift to proactive thermal monitoring is crucial. Implementing thermal imaging during routine checks can identify hot spots early. Therefore, corrective action can be taken before failure occurs. This proactive stance significantly reduces unscheduled downtime. It also enhances the overall safety and productivity of the factory automation line. This is a clear indicator of a mature maintenance program.

Application Case: Optimizing Control Panel Life

Prolonging the life of your control systems requires premium cooling solutions. Powergear X Automation Limited offers high-performance thermal management products. They help protect your sensitive PLCs, DCS, and VFDs from destructive heat.

| Model | Cooling Capacity (BTU/hr) | Features | Best Application |

| CoolMax 2500 | 2,500 | Compact design, high efficiency, basic display. | Small-to-Mid Enclosures, Clean Environments |

| ThermoGuard 6000 | 6,000 | Robust construction, integrated condensate evaporator, IoT monitoring ready. | Mid-to-Large Enclosures, High Heat Loads |

| EcoCool 4000 | 4,000 | Energy-saving inverter technology, NEMA 4X rated (corrosion resistant). | Outdoor/Washdown Areas, Energy Critical Sites |

Selection Guidance:

- For a compact panel with a moderate heat load in a clean indoor setting, the CoolMax 2500 offers a cost-effective, efficient solution.

- If your enclosure is large, houses multiple VFDs, and requires robust monitoring, the ThermoGuard 6000 provides necessary capacity and advanced features.

- When environmental protection (dust, water, corrosion) and energy savings are top priorities, the EcoCool 4000 with its NEMA 4X rating and inverter technology is the ideal choice.

Protect Your Investment Now. Click here to explore the full range of Powergear X Automation Limited cooling products and secure your system’s longevity.