Bently Nevada 3300 NSv Probe: Solving Tight Space Vibration Monitoring

Optimizing Vibration Monitoring with Bently Nevada 3300 NSv Probes

Modern industrial automation relies on precise data to prevent catastrophic machine failure. While standard 8 mm proximity probes serve most factory automation needs, tight mechanical constraints often require a specialized approach. The Bently Nevada 3300 NSv (Narrow Side-view) system bridges this gap by providing high-accuracy sensing in confined spaces. At Powergear X Automation, we observe that selecting the right sensor geometry is as critical as the control system logic itself.

The Practical Hurdles of Standard Proximity Probes

Conventional 8 mm sensors are the workhorses of condition monitoring. However, their physical footprint creates significant integration hurdles in compact machinery. These probes require a large “view” area to maintain a stable linear range. When a shaft surface is too narrow, the magnetic field “bleeds” over the edges. Consequently, this causes signal distortion and false vibration readings. Furthermore, standard probes often demand excessive radial clearance, which many modern high-speed pumps simply do not have.

Engineering Benefits of the Narrow Side-view Design

The 3300 NSv probe features a specialized tip designed for lateral precision. Unlike standard probes that project a wide electromagnetic field, the NSv focuses its energy. Therefore, it can monitor narrow target “lands” without interference from adjacent shoulders or bearings. This design is essential for technicians who must retrofit legacy DCS or PLC systems with modern protection hardware. In addition, the probe’s smaller diameter reduces the risk of mechanical contact during thermal expansion cycles.

Reliability in High-Pressure Process Environments

Industrial compressors often operate under extreme pressure and gas density. These conditions can fluctuate, affecting the dielectric constant of the medium between the probe and the shaft. The 3300 NSv is engineered to maintain signal integrity despite these environmental shifts. Its robust construction ensures that chemical exposure does not degrade the sensor tip over time. As a result, maintenance teams experience fewer “nuisance trips” and more consistent data trends.

Seamless Integration with Industrial Control Systems

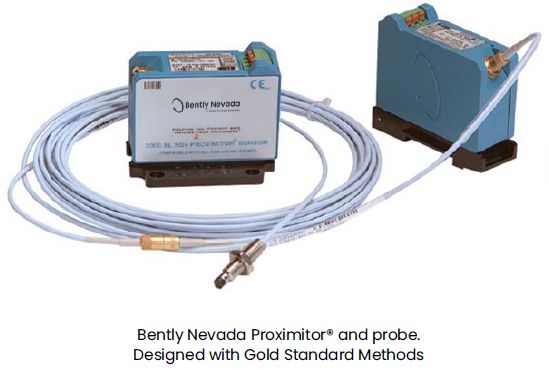

A major advantage of the 3300 NSv is its backward compatibility. It integrates directly into existing Bently Nevada 3300 or 3500 monitoring racks. This compatibility reduces the need for extensive rewiring or hardware overhauls. For engineers managing complex factory automation projects, this modularity saves significant time during commissioning. Moreover, the calibration remains stable, ensuring long-term trust in the automated safety shutdown systems.

Expert Perspective from Powergear X Automation

In our experience at Powergear X Automation, we see many facilities struggle with “side-view” interference on small gearboxes. Standard probes often pick up the movement of nearby gears rather than the shaft itself. We recommend the 3300 NSv because its narrow field of view ignores peripheral metal surfaces. Choosing the right probe isn’t just about the sensor; it’s about understanding the specific mechanical envelope of your asset.

Technical Highlights and Specifications

Miniature Footprint: Fits into bores as small as 1/4-28 or M8 threads.

Target Precision: Operates on targets as narrow as 6 mm (0.25 inches).

Chemical Resistance: Specifically designed to withstand corrosive process gases.

Linear Range: Provides a reliable 1.0 mm (40 mil) operating range.

System Compatibility: Fully supports 3300 XL Proximitor® sensor interfaces.

Application Scenarios

High-Speed Turbochargers: Where shaft diameters are too small for standard 8 mm probes.

Aero-derivative Gas Turbines: Locations with extreme space constraints near the bearing housing.

Reciprocating Compressor Rods: Measuring rod drop in environments with limited axial clearance.

Centrifugal Pump Retrofits: Adding vibration monitoring to older pumps with tight seal chambers.

To find the best hardware for your specific machinery protection needs, visit the specialists at Powergear X Automation. We provide the technical expertise to ensure your assets stay online and optimized.

Frequently Asked Questions (FAQ)

Q: Can I replace an 8 mm probe with an NSv probe without changing the Proximitor?

A: No, you must use the specific 3300 NSv Proximitor. The electrical characteristics of the smaller coil require a matched driver to maintain the correct scale factor and linearity.

Q: What is the biggest mistake during the installation of NSv probes?

A: In our field experience, the most common error is improper gapping. Because the linear range is shorter than standard probes, installers must use a digital voltmeter to set the “DC Gap” precisely at the midpoint.

Q: Does the NSv probe work on all types of metal shafts?

A: Like most eddy-current sensors, it is calibrated for 4140 steel. If your shaft uses a different alloy, the system requires custom calibration to ensure the vibration readings are accurate.