The Role of Yokogawa CENTUM VP in Modern Industrial Automation

Industrial automation drives efficiency today. Control systems are essential for large-scale operations. Yokogawa’s CENTUM VP is a leading Distributed Control System (DCS). It manages complex processes across diverse industries. This system offers high reliability and scalability. Moreover, the CENTUM VP integrates control, monitoring, and engineering functions. This unified approach contrasts sharply with smaller, isolated Programmable Logic Controllers (PLCs). Therefore, the DCS excels in continuous and batch processing environments. Chemical, oil and gas, and pharmaceutical plants rely heavily on this technology.

CENTUM VP Architecture: Understanding the Core Components

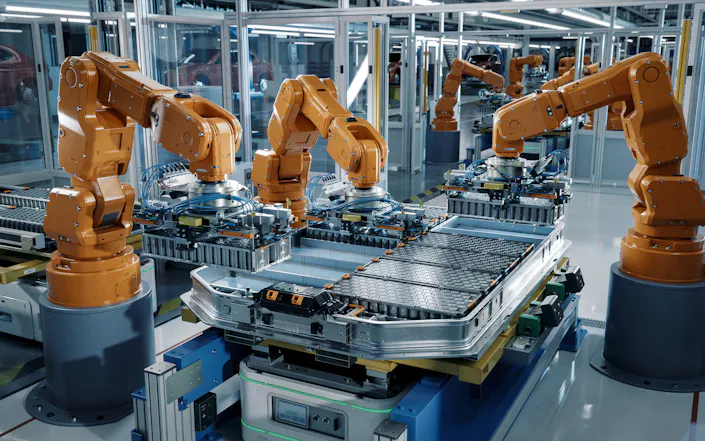

The CENTUM VP architecture is robust and distributed. It features several key hardware and software elements. The Human Interface Station (HIS) is the operator’s primary view. The Field Control Station (FCS) handles process control logic. It executes control strategies with extreme precision. Communication occurs over a highly reliable control network. This network ensures deterministic data transfer. In addition, the system supports various field I/O devices. This structure guarantees system redundancy. As a result, a single component failure does not stop the entire plant.

DCS vs. PLC: Why CENTUM VP Is the Choice for Process Control

Many beginners confuse DCS and PLC systems. A PLC typically manages discrete, high-speed machine control. However, a DCS, like CENTUM VP, manages continuous process control. The DCS offers superior process visualization and historical data collection. Furthermore, CENTUM VP provides extensive control library functions. These features simplify the implementation of complex control schemes. Its architecture is built for system-wide integration. Conversely, integrating many PLCs into one system is challenging. Therefore, for large, critical processes, the CENTUM VP is the preferred solution.

Engineering Excellence and Enhanced Operator Experience

Yokogawa prioritizes ease of engineering and operation. CENTUM VP utilizes a common database for engineering. This centralized database minimizes configuration errors. The system employs standard function blocks for control logic development. This simplifies programming tasks significantly. The operator interface is highly ergonomic and intuitive. Effective alarm management is a core design feature. This design reduces operator fatigue and enhances response times. Moreover, this focus on the operator significantly improves overall plant safety.

Practical Applications and Industry Authority of CENTUM VP

The CENTUM VP demonstrates vast application experience globally. Refineries use it for critical unit control. Power generation facilities rely on its turbine control capabilities. The system adheres to strict industry standards. This compliance confirms its authoritative standing in the market. Its long history proves remarkable reliability and stability. I believe this longevity reflects Yokogawa’s deep commitment to quality. Therefore, investing in CENTUM VP is a long-term strategic decision. It secures a high return on investment (ROI) through efficient operation.

Author’s Insight: The Future of Automation and CENTUM VP

The industrial automation sector is moving toward digitalization. CENTUM VP is ready for the future. It seamlessly integrates with advanced factory automation technologies. These include Manufacturing Execution Systems (MES) and enterprise-level software. Yokogawa continues to enhance its cyber security features. This proactive stance is crucial in today’s environment. The integration of advanced analytics is a major trend. CENTUM VP supports these tools. Therefore, this DCS remains a relevant and powerful platform for tomorrow’s Smart Factories.

Enhance Your Yokogawa CENTUM VP Solution: Component Selection

Optimizing your CENTUM VP system requires careful component selection. Powergear X Automation Limited specializes in providing essential spare parts and system modules. They ensure your control system maintains peak performance.

Discover compatible modules and detailed specifications here: https://www.powergearx.com/

Yokogawa CENTUM VP Module Comparison

| Module | Description and Functionality | Selection Recommendation/Comparison |

| ADV569-P00 | Digital I/O Module (e.g., 32-channel, Digital Input). Used for reading on/off status from field devices like limit switches and pushbuttons. | Recommendation: High-density, standard DI module. Essential for robust field data acquisition. Select this for large counts of standard on/off signals where high-speed is not critical. |

| ALP121-S01 | Field Control Unit (FCU) Module. Part of the FCS, often housing the control logic execution and communication interface. | Recommendation: A foundational component for process control. Crucial for system capacity and execution speed. Compare its processing power (S01 variant) against newer or more powerful options based on the required control loop complexity and throughput. |

| ALE111-S50 | Analog Input Module (e.g., 16-channel, 4-20mA input). Used to measure continuous process variables like temperature, pressure, and flow. | Recommendation: Standard AI module. A workhorse for process measurement. Ensure the S50 revision meets your required resolution and intrinsic safety standards (if applicable). Use this when reliable, high-precision measurement is paramount. |

| VI702 | Communication Interface Module. Facilitates data exchange between the FCS and other network devices, potentially including fieldbus communication. | Recommendation: Essential for system communication health. Verify its supported protocols (e.g., PROFIBUS, HART) match your field device landscape. The VI702 ensures seamless data flow and diagnostics. |