SCP401-11 Sync Link Guide: Ensuring Controller Redundancy

Troubleshooting the Yokogawa SCP401-11 Sync Link LED for Reliable Redundancy

The Critical Role of Synchronization in Process Control

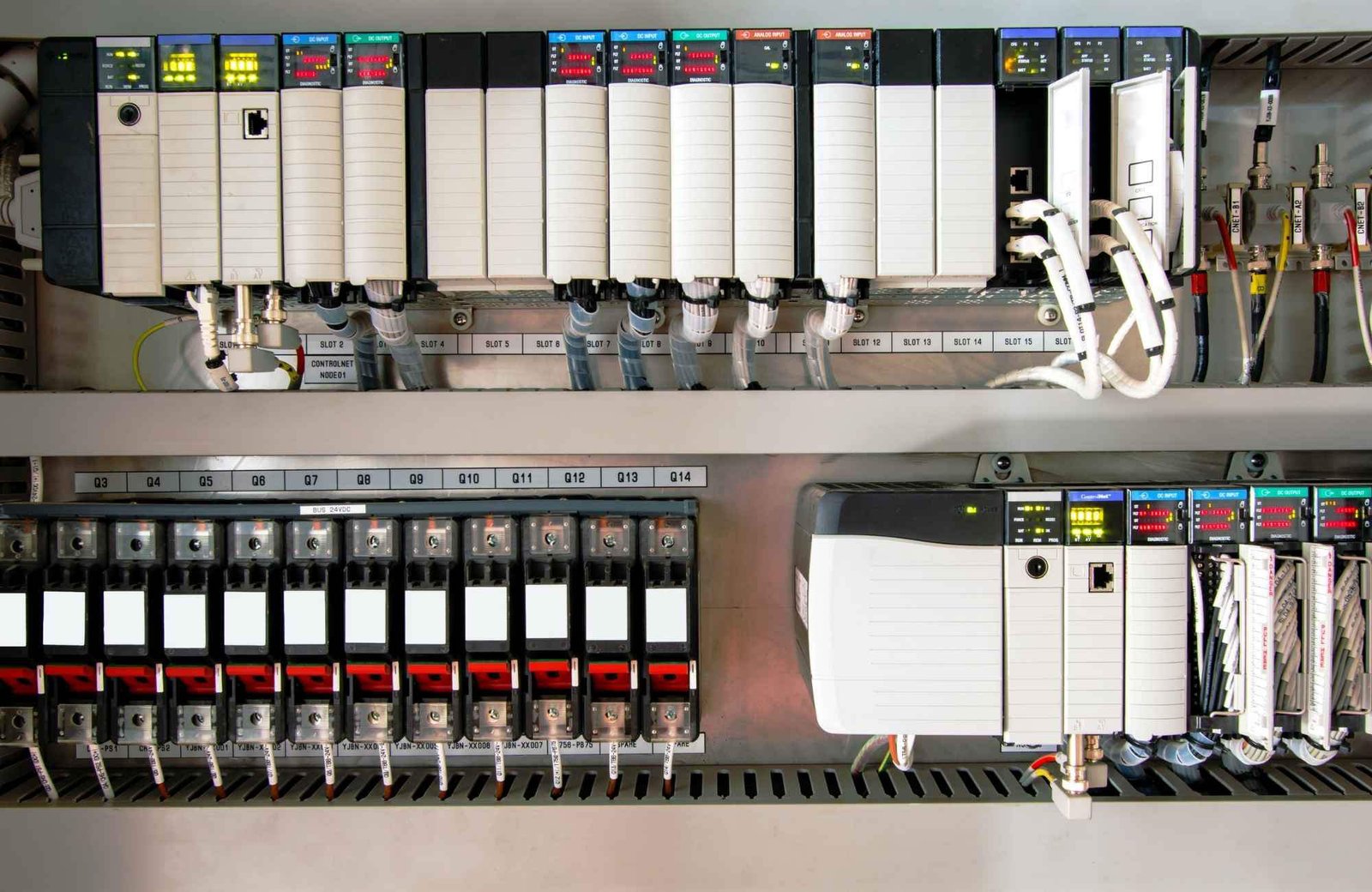

In the world of industrial automation, the Yokogawa SCP401-11 serves as a cornerstone for CENTUM VP and CS 3000 architectures. The Sync Link LED is a vital health indicator for the system. A dark LED signals a disruption in deterministic control execution. Consequently, the system faces risks during CPU switchovers. Maintaining a lit Sync Link LED ensures data consistency across redundant pairs. This reliability is essential for high-stakes industries like oil, gas, and chemical refining.

The Technical Mechanics of the Sync Link Channel

The Sync Link is a dedicated, point-to-point hardware channel, not a standard Ethernet port. It facilitates real-time data mirroring between paired SCP401-11 units. Powergear X Automation observes that many engineers mistake a “RUNNING” status for a healthy system. However, without synchronization, redundant CPUs operate asynchronously. This state often leads to non-bumpless transitions during a failure. Therefore, you must prioritize the hardware link to meet IEC 61511 high-availability standards.

Common Physical Layer Failures and Slot Mismatch

Physical connectivity issues frequently cause the Sync Link LED to remain unlit. Engineers must use Yokogawa-specified synchronization cables for these connections. In addition, the redundant processors must occupy identical slot positions in the control unit. During hectic plant turnarounds, maintenance teams often swap cables or move modules incorrectly. As a result, the hardware fails to establish a handshake. Always verify that both CPUs reside in matching slots to restore the link.

Firmware Compatibility and System Generation Alignment

Firmware discrepancies represent a hidden threat to factory automation stability. The SCP401-11 requires identical firmware revisions across the redundant pair. Mixing older and newer versions during a partial upgrade can silently disable the synchronization feature. Moreover, system software versions in CENTUM VP must support the specific SCP hardware revision. Therefore, senior engineers always perform a firmware audit before commissioning new modules on-site.

Strategic Maintenance for High-Vibration Environments

Offshore platforms and compressor stations present unique challenges for control systems. Constant vibration can cause micro-disconnections in the Sync Link cabling. Powergear X Automation recommends using robust strain relief for all dedicated sync cables. Furthermore, you should avoid tight bending radii that might degrade signal integrity over time. Regular physical inspections during shutdowns prevent intermittent synchronization alarms that are difficult to diagnose remotely.

Powergear X Automation Expert Commentary

At Powergear X Automation, we view a dark Sync Link LED as a leading indicator of future downtime. Modern DCS environments are resilient, but they are not invincible. A silent failure in redundancy often goes unnoticed until a primary CPU fails. We suggest implementing a “Physical Health Check” protocol. This ensures that field technicians verify LED statuses daily, rather than relying solely on software diagnostics.

Best Practices for SCP401-11 Implementation

- ✅ Confirm the Sync Link LED is steady and not blinking.

- ✅ Verify “Synchronized” status using the Engineering Station (ENG) tools.

- ✅ Use only genuine Yokogawa synchronization cables for all pairs.

- ✅ Document firmware versions during every hardware replacement.

- ✅ Ensure the pair resides in the same logical and physical slots.

- ✅ Check for mechanical strain on ports in high-vibration areas.

Real-World Application Scenarios

In a large-scale petrochemical refinery upgrade, a client reported unexpected process trips during routine testing. Our investigation revealed that the standby SCP401-11 had a slightly older firmware version. Although the primary unit was healthy, the Sync Link was inactive. After aligning the firmware and replacing a damaged sync cable, the LED returned to green. This restored the “bumpless” switchover capability, protecting the plant from million-dollar losses.

Frequently Asked Questions (FAQ)

Q1: Does a dark LED always indicate a hardware failure in the SCP401-11?

Usually, no. Most issues stem from cabling errors, firmware mismatches, or incorrect slot placement. Hardware failure is rare but possible if the LED remains off after checking all physical and software parameters.

Q2: Can I mix an SCP401-11 with an older SCP model in the same pair?

We strongly advise against this. For optimal redundancy, always use a matched pair of identical processors. Mixing generations often leads to synchronization timeouts and unpredictable control behavior.

Q3: What is the first step if the Sync Link fails after a CPU replacement?

First, check the firmware version of the new unit against the existing primary unit. If they match, inspect the sync cable for seated pins or damage sustained during the installation process.

Ready to optimize your control system reliability? Visit Powergear X Automation for premium components and expert technical support.