Unlocking Critical Control: A Deep Dive into Siemens S7-400 High-Availability Components

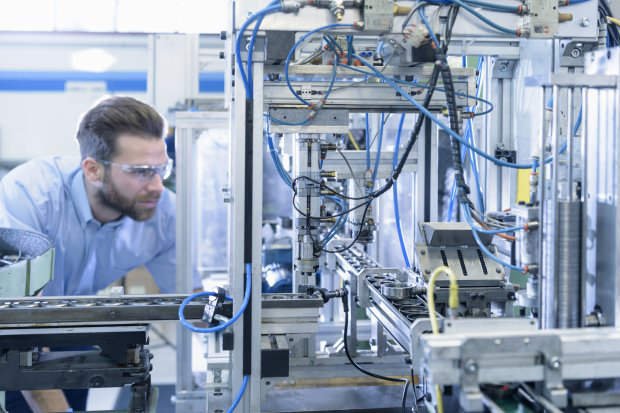

The backbone of modern industrial automation relies on robust, fault-tolerant control. Siemens’ SIMATIC S7-400 series, especially the ‘H’ (High-Availability) line, meets this demanding need. This platform is specifically designed for systems that cannot tolerate downtime. It ensures continuous operation in critical applications like process industries and infrastructure. We will examine four crucial components within this powerful control systems ecosystem.

The Foundation: 6ES7400-2JA00-0AA0 S7-400H UR2-H Rack

This component is not a controller but the essential physical chassis. The UR2-H rack provides the necessary structure for the S7-400H system. It features 18 slots, ready for the high-availability configuration. This industrial frame physically supports redundant CPU and I/O modules. The key operating principle is mirrored functionality across two separate racks. Furthermore, this dual-rack setup enables hot-swapping during operation.

Technical Highlights of the Rack:

✅ Function: Physical housing and backplane for S7-400H components.

⚙️ Principle: Supports the redundant operation of two separate PLCs.

🔧 Application: Required for all S7-400H applications, ensuring system redundancy.

Network Integration: 6GK7443-1EX30-0XE0 CP 443-1 PROFINET Module

System connectivity is paramount in factory automation. The CP 443-1 is a powerful communications processor (CP) for the S7-400. It enables seamless integration into Industrial Ethernet and PROFINET networks. This module handles both vertical and horizontal data exchange. Moreover, it supports extensive communication protocols like S7-communication and Open TCP/IP. This connectivity is vital for DCS integration.

The use of PROFINET allows for real-time data exchange. This feature is crucial for time-sensitive applications. Therefore, the module acts as a powerful data gateway between the PLC and the plant network. According to a recent Markets report, PROFINET adoption is rapidly increasing globally.

Author’s Insight: The CP 443-1 is the ‘digital tongue’ of the S7-400. Its capabilities significantly reduce complexity in networking different devices. Choosing this specific CP ensures future compatibility with modern IIoT standards.

The Powerhouse: 6ES7414-5HM06-0AB0 High Availability Automation CPU

This particular model, the CPU 414-5H, is designed for medium-to-high performance control. Its primary function is reliable and fast processing of control tasks. This CPU operates on a redundant principle. Two such modules work simultaneously (synchronous hot-standby). If one CPU fails, the second immediately takes over with zero data loss. This switchover is completely bumpless and undetectable by the process. As a result, critical control processes maintain continuity.

Selection Difference: This CPU offers a strong balance of performance and cost. It is often chosen for medium-sized, high-availability process units.

Ultimate Performance: 6ES7410-5HX08-0AB0 CPU 410-5H Process

For the most demanding applications, the CPU 410-5H stands as the ultimate controller. This specialized processor is tailored for the SIMATIC PCS 7 DCS (Distributed Control System). It provides exceptional performance and vast memory. Its core principle is maximum processing speed for large-scale process control. Furthermore, it meets the highest standards for fault tolerance and environmental resilience.

This CPU is an integral part of safety instrumented systems (SIS). It uses advanced redundancy mechanisms. Therefore, it is the de facto choice for mission-critical operations.

Comparative Selection: Distinguishing the CPUs

Choosing between the two H-CPUs depends entirely on application scope.

- Feature

CPU 414-5HM06-0AB0 (Automation)

CPU 410-5HX08-0AB0 (Process) - Primary Focus

General high-availability PLC applications.

Integrated control within the SIMATIC PCS 7 DCS. - Performance Level

Medium-High.

Highest (Dedicated Process Controller). - Principle

Synchronous Hot-Standby PLC.

Integrated PCS 7 Controller, High-Performance DCS. - Typical Use

Water treatment, power generation balance-of-plant.

Oil & Gas, refining, chemical plants (SIS/Process).

Application Cases and Solutions

High-availability components are indispensable where human life or the environment is at risk. They are also necessary where economic losses from downtime are catastrophic.

- Oil and Gas: The CPU 410-5H is typically used to manage emergency shutdown systems (ESD) and fire and gas systems (F&G).

- Pharmaceuticals: CPU 414-5H controls critical batch reactors. A faultless switchover maintains product quality and compliance.

- Infrastructure: Traffic control systems and major power grid stations use the UR2-H Rack to ensure 24/7 operation despite component failure.

- Cybersecurity: The CP 443-1 is essential for segmenting the control network. It protects the critical S7-400 controller from external threats.

Powergear X Automation Comment: In my experience, the upfront investment in S7-400H hardware is negligible compared to the cost of a single hour of unplanned downtime in a chemical plant. This series provides an unmatched level of trust (Trustworthiness) in the industrial automation sector.

Frequently Asked Questions (FAQ)

1. What is the most critical setup step for the S7-400H system?

Experience shows that correctly configuring the PROFIBUS/PROFINET redundancy is vital. You must use specialized synchronization fiber optic cables. This cable ensures that both CPUs operate in perfect sync, guaranteeing a seamless takeover upon failure.

2. How do I effectively troubleshoot a CP 443-1 network issue?

Start by checking the module’s diagnostic buffer. The most common error is an incorrect IP parameter or subnet mask. Always use the Primary Setup Tool (PST) or STEP 7 diagnostics. Additionally, ensure the latest firmware is running for optimal performance.

3. What is the biggest mistake people make when migrating to S7-400H?

The most common error is underestimating the programming complexity for I/O redundancy. The system requires special function blocks (FBs) for redundant I/O modules. Do not treat it as a standard S7-400 project; proper engineering is a must.

Ready to enhance your industrial control system’s reliability and performance?

Learn more about these and other specialized industrial automation solutions. Click here to explore the full range of products offered by Powergear X Automation today: https://www.powergearx.com/