🌐 Industrial Ethernet in Modern Automation

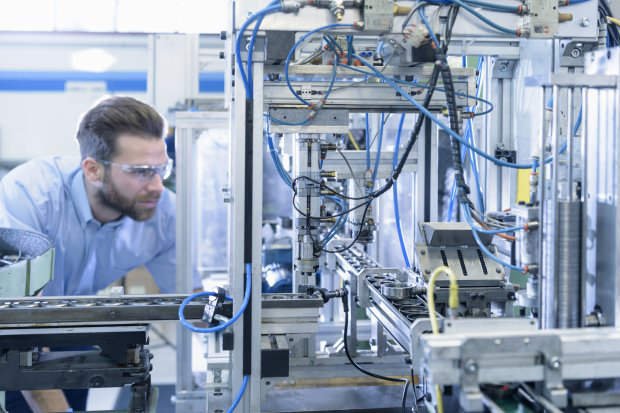

Industrial Ethernet forms the digital backbone of machine, process, and building automation.

It enables real-time control, remote monitoring, and IIoT connectivity across modern plants.

With Industry 4.0 accelerating data exchange between PLCs, sensors, HMIs, and cloud systems, reliable connectors and cabling now determine long-term performance and uptime.

🏭 Where Industrial Ethernet Connects Your Plant

From control cabinets to field devices, Ethernet connects PLCs, drives, and edge computing units.

Common protocols—such as Ethernet/IP, PROFINET, Modbus TCP, and EtherCAT—rely on stable CAT6A connectivity to ensure synchronization and throughput.

➡️ Explore Industrial Ethernet solutions at Powergear X Automation

⚡ Why Network Capacity Will Stress Existing Systems

Global IIoT expansion means billions of connected industrial nodes.

By 2025, total data volume may exceed 180 ZB, placing huge stress on legacy networks.

Plants must adopt cabling that supports higher bandwidth, lower latency, and improved EMI immunity — all of which CAT6A delivers.

🚀 Choose CAT6A for Future-Proof Performance

CAT6A supports 10 Gbps Ethernet with extended bandwidth up to 500 MHz.

According to TIA-568 and ISO/IEC 11801 standards, CAT6A is the preferred medium for new high-density installations.

Key benefits:

- 10G-ready backbone for Industrial Ethernet

- Reduced crosstalk and interference

- Superior shielding for EMI-heavy environments

- Backward compatibility with CAT6 and CAT5e

🧱 Ruggedization: Vibration, Shock, and Bending

Industrial environments expose connectors to vibration, shock, and mechanical stress.

Select RJ45 solutions tested above IEC minimums—for example, 20g vibration and 30g shock tolerance.

These ensure signal stability in robotics, heavy equipment, and production lines.

🔒 EMI, EMC, and ESD Protection

Industrial noise can degrade Ethernet signals and device reliability.

Choose RJ45 connectors with:

- 360° full-metal shielding

- Tested ESD protection

- Grounded panel connections

- Such designs maintain signal integrity under strong electromagnetic interference.

🌡 Operating Temperatures and Outdoor Use

For outdoor or harsh settings, ensure components withstand temperature and moisture extremes.

Look for:

- Wide operating temperature range (-40°C to +85°C)

- UV-resistant housings

- Ingress protection (IP67/IP68) when exposed to dust or water

🔗 Protocol Compatibility and Integration

J45 connectors should support:

EtherCAT

PROFINET

Modbus TCP

Ethernet/IP

Universal compatibility simplifies system upgrades, maintenance, and multi-vendor integration—key for Industry 4.0 convergence.

🧰 Integration and Assembly Features

To streamline installation:

- Choose multiport modules and panel-mount connectors

- Consider SMD/THR soldering types

- Use integrated LED indicators for status feedback

- ➡️ These features reduce wiring time and enable faster fault diagnosis.

📈 Industry Evidence and Market Context

The industrial Ethernet market exceeded USD 11 billion in recent years and continues to grow at a steady CAGR toward 2030.

The migration from fieldbus to Ethernet underscores the need for CAT6A-class cabling and ruggedized RJ45 connectors.

(Sources: MarketsandMarkets, IMARC Group, IEEE, Phoenix Contact Technical Reports)

🔧 Practical Recommendations from Field Experience

Deploy CAT6A shielded copper for horizontal runs.

Use RJ45 connectors rated for industrial shock and EMI resistance.

Test assemblies under real vibration, temperature, and humidity before rollout.

🌟 Product Spotlight: Phoenix Contact Industrial RJ45

Phoenix Contact provides CAT6A industrial RJ45 connectors designed for harsh factory conditions.

Specifications:

✅ CAT6A up to 10 Gbps

⚙️ Vibration 20g, Shock 30g, Bending Retention 30 N

🔧 EMI/ESD: 360° shielding

📎 Learn more on Phoenix Contact’s CAT6A RJ45 product page

🧩 Application Scenarios and Deployment Tips

- Typical use cases:

- Field cabling and control cabinets

- Robotic systems and sensor networks

- Outdoor and mobile equipment

- Checklist for engineers:

- Map device locations and noise sources.

- Use shielded CAT6A cables and connectors in EMI-prone zones.

- Validate assembly under vibration, temperature, and ESD stress.

🧠 Author Insight: Invest Early in Reliability

Investing in high-quality connectors and standardized cabling prevents future downtime and rewiring costs.

Consistency in components simplifies maintenance and spare part logistics.

❓ FAQs

- Q1: Do I need CAT6A everywhere?

Use CAT6A for 10 Gbps, long cable runs, or high EMI zones. In other cases, CAT6 may suffice. - Q2: How important is connector ruggedization?

Very. Rugged connectors reduce downtime in vibration-heavy or outdoor environments. - Q3: Can I mix fieldbus and Ethernet devices?

Yes—but plan gateways and bridges, and use connectors compatible with common stacks (Ethernet/IP, PROFINET).

🧭 Call to Action

Ready to upgrade your Industrial Ethernet infrastructure?

👉 Visit Powergear X Automation to explore CAT6A RJ45 solutions and expert integration support.

📚 References

- Markets and Markets: Industrial Ethernet Market Report

- IMARC Group: Industrial Ethernet Growth Analysis

- Phoenix Contact: CAT6A RJ45 Datasheets

- TIA-568 Cabling Standards Overview

- Global Data Growth Projections, 2025 (IDC/Statista)