Troubleshooting the PowerFlex 700: Stop the Power Cycle Madness

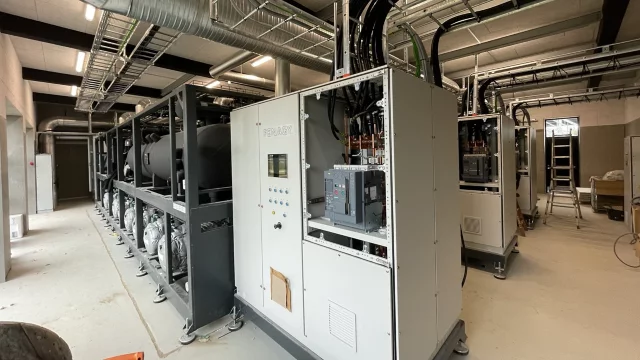

You have just installed a new variable frequency drive (VFD). However, your new Allen-Bradley PowerFlex 700 drive is stuck in a frustrating power-cycling loop. This happens even with no motor connected and the input voltage stable. This scenario is rare, but it is a critical issue in industrial automation setups. Before you assume a warranty return, experienced technicians suggest a series of focused diagnostic steps. This post, brought to you by Powergear X Automation, explores the common causes of this restart issue. We will guide you through effective troubleshooting to minimize downtime in your factory automation line.

The Power Cycle Puzzle: Common Culprits in PowerFlex Drives

A PowerFlex 700 drive that instantly begins rebooting is not always defective. According to industry data, control systems failures of this type are often isolated to peripheral or interface components. Therefore, a complete drive replacement is frequently unnecessary. Understanding the component hierarchy is the first step toward efficient resolution.

Human Interface Module (HIM) Failure: A faulty HIM is a prime suspect. If this display unit or its internal logic fails, it can send continuous reset signals. This causes the drive to cycle even without load.

The T-Board Interface or Socket Damage: The T-Board serves as the crucial connection point for the HIM and any communication modules. A loose ribbon cable, corroded pins, or a cracked socket can break the continuous data flow. As a result, this connectivity failure triggers protective restarts.

Instability in the Internal Power Supply: The main power supply board may experience component drift or a failure in the smoothing capacitors. This can lead to unstable DC bus voltage, which is instantly interpreted as a fault by the main logic board.

Control Board Malfunction: A less common, yet serious, cause is a failure on the main control systems board itself. This could involve critical firmware memory or a logic gate failure.

Improper Wiring or Terminal Tightness: Loose connection points on the input terminals can lead to momentary voltage dips or spikes. The drive’s protective circuits will react instantly, causing the seemingly random reset.

Expert-Backed Steps for Fast Diagnosis

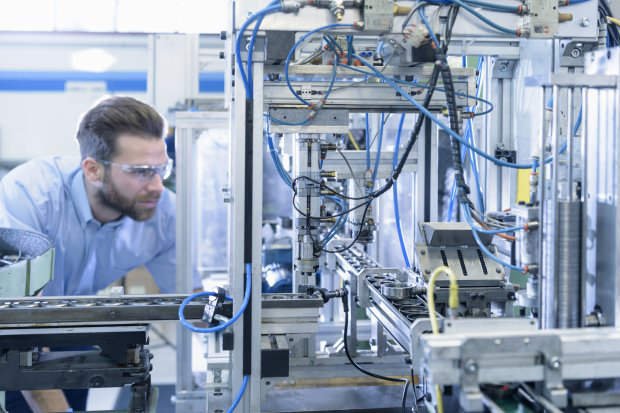

When dealing with a new PowerFlex 700 cycling, quick and methodical steps are key to diagnosing the true root cause. Electrical engineers in industrial automation recommend a non-invasive approach first.

Detach the HIM Module Immediately: Disconnecting the Human Interface Module is the most critical first step. If the power cycling stops, the fault is isolated to the HIM or the T-Board socket. Therefore, this simple action immediately halves the scope of the problem.

Swap for a Verified Working HIM: If available, substitute the suspect HIM with one from a known, working drive. If the PowerFlex 700 stabilizes, the original HIM is the defective component. However, if the cycling continues, the T-Board is the likely next candidate.

Utilize Rockwell Software Tools: Technicians should connect to the drive using an interface like the 1203-USB. Software like DriveExecutive or Connected Components Workbench (CCW) allows stable communication. If the drive allows reliable data reading, the core drive logic and power stage are probably sound. This data access helps pinpoint configuration issues or read the exact fault history.

A Detailed Inspection of Physical Connections: Power down and lock out the system before any physical check. Carefully inspect the T-Board socket and surrounding connection points. Look for bent pins, debris, or oxidation that suggests a poor electrical connection. In addition, ensure the input power terminals are torqued to the manufacturer’s specification.

Industry Insight: Many field engineers report that over 40% of initial drive instability issues are resolved by simply addressing loose terminal blocks or minor component seating issues.

Author’s Viewpoint: Minimizing Downtime and System Integrity

The introduction of modern VFDs like the PowerFlex 700 into PLC and DCS environments is critical. Their reliable function underpins the efficiency of modern manufacturing. This is the opinion of Powergear X Automation. We find that proper initial staging is the best defense against these start-up errors.

Bench Test Best Practice: Always power up the VFD on a test bench before final installation into the cabinet. This simple step validates the drive’s core function. It eliminates external wiring as a variable.

The Value of Spares: Maintaining a small stock of critical spare parts, particularly HIMs and I/O boards, is essential. Swapping a peripheral component is faster than a full drive replacement. This practice dramatically reduces Mean Time To Repair (MTTR).

We advocate for buying certified, pre-tested components. Each PowerFlex 700 we supply is thoroughly inspected by our in-house technicians. We back every unit with a 2-year warranty for full assurance.

When a Warranty Claim Becomes Necessary

If the drive continues to cycle after removing the HIM, checking the T-Board, and verifying all input voltages, the core unit is likely defective. Therefore, this final determination mandates initiating a Return Material Authorization (RMA) process.

System Integrity Checklist

Voltage Verified: Input voltage confirmed stable and within the ±10% tolerance.

Peripherals Removed: HIM and any communication modules are detached.

Terminals Secure: All power and control terminals are securely tightened.

No Fault Log: The drive cannot maintain power long enough to log a clear, persistent fault.

Document every troubleshooting step clearly before contacting your supplier. This documentation accelerates the warranty process.

Solutions & Support from Powergear X Automation

Whether you are implementing a complex DCS upgrade or need an emergency replacement, system reliability is paramount. Powergear X Automation specializes in providing fully tested and verified PowerFlex 700 drives. We help engineers and maintenance teams keep their industrial automation lines running. Click here to explore our inventory and learn how our quality guarantee can support your operational uptime: https://www.powergearx.com/

Frequently Asked Questions (FAQ)

Q1: How can I check for a T-Board failure without a spare T-Board?

A: A definitive check without a spare is difficult. However, after removing the HIM, if the drive still cycles, the problem is deeper. If you can establish a stable serial connection using CCW but the drive remains unstable, the T-Board’s interface to the main board is often the issue. Look closely for physical damage or loose screws holding the T-Board in place.

Q2: Will a parameter conflict cause a new PowerFlex 700 to power cycle?

A: Yes, it is possible but less common than a hardware fault. If a default parameter setting conflicts severely with the actual installation (e.g., motor parameters outside the drive’s capability), the drive’s pre-boot check can trigger an immediate fault. This can look like a reset. Try using the software to perform a factory reset to eliminate this possibility before assuming a hardware failure.

Q3: What kind of physical damage should I look for on the control board?

A: Look for signs of overheating, such as discolored components or a burnt smell. Pay close attention to the electrolytic capacitors—if they appear bulging or leaking fluid, they have failed. This is a common indicator of a power supply or filtering issue that will certainly cause unstable cycling.