Introduction

As an operations manager with years of experience in industrial control, I’ve seen firsthand how crucial it is to keep systems running smoothly without breaking the bank. Maintenance costs can quickly spiral out of control, eating into profits and causing unexpected downtime. But what if there was a way to predict issues before they cause failures and fix problems without shutting everything down? That’s where predictive diagnostics and hot-swappable modules in RX3i systems come into play. These technologies are game-changers for any operation looking to optimize efficiency and drastically reduce expenses.

The Hidden Cost of Reactive Maintenance

Many operations still rely on reactive maintenance – fixing things only after they’ve broken. While seemingly straightforward, this approach is incredibly costly. Imagine a critical component failing unexpectedly. Production stops, and you’re scrambling to find parts and technicians. The resulting downtime, lost output, and expedited shipping fees for replacement parts quickly add up. This “fix-it-when-it-breaks” mentality also often leads to more extensive damage because a small issue can escalate into a major system failure if not caught early.

Embracing Predictive Diagnostics: Your Crystal Ball for System Health

This is where predictive diagnostics shines. Instead of waiting for failure, predictive diagnostics uses data from your RX3i system to anticipate potential issues. Think of it as having a crystal ball for your equipment’s health. Your RX3i system, with its advanced capabilities, can monitor parameters like temperature, voltage, and current, and identify subtle deviations that indicate a problem is brewing.

My unique insight here is that it’s not just about collecting data; it’s about understanding what that data tells you. For example, a slight, consistent increase in a module’s operating temperature over time, even if it’s within “acceptable” limits, could be an early warning sign of impending failure. By setting up alerts based on these trends, you can schedule maintenance proactively during planned downtime, avoiding costly emergency repairs and unexpected production halts. This shifts you from a reactive to a proactive maintenance strategy, saving significant money and stress.

The Power of Hot-Swappable Modules: Repair Without Downtime

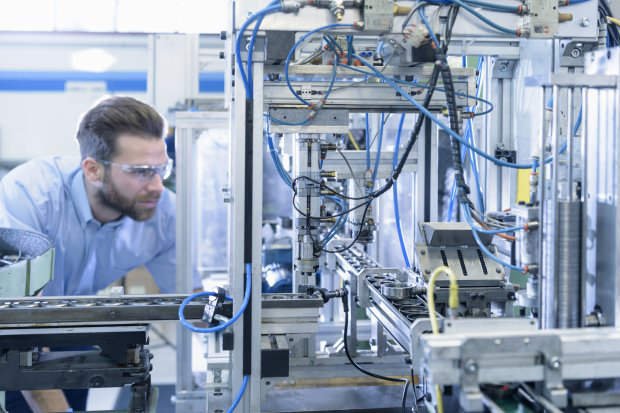

While predictive diagnostics helps you foresee problems, hot-swappable modules in RX3i systems allow you to address them with minimal disruption. “Hot-swappable” means you can replace a faulty module while the rest of the system remains powered on and operational. This is a massive advantage over systems that require a complete shutdown for module replacement.

Consider a situation where a minor I/O module shows an error. With a hot-swappable design, your maintenance team can simply pull out the old module and insert a new one without interrupting the entire production line. This drastically reduces downtime from hours to mere minutes. From my perspective, this capability is not just about convenience; it’s about maintaining continuous operation. Every minute your system is down, you’re losing money. Hot-swappable modules help you minimize these losses, ensuring that your facility runs as close to 24/7 as possible.

Integrating for Maximum Savings

The true power lies in combining these two strategies. Predictive diagnostics tells you when a module is likely to fail, and hot-swappable modules allow you to replace it without halting operations. This synergy leads to a significant reduction in maintenance costs. You’ll spend less on emergency repairs, reduce spare parts inventory (because you’re replacing parts based on need, not just in case), and drastically cut down on lost production time.

Ready to Optimize Your Operations?

Cutting maintenance costs isn’t just a goal; it’s a strategic imperative for any industrial operation. By leveraging the advanced features of RX3i systems, specifically predictive diagnostics and hot-swappable modules, you can transform your maintenance strategy from a costly burden into a streamlined, efficient process that boosts your bottom line.

To learn more about how RX3i systems can revolutionize your maintenance approach and explore high-quality components, click here to browse the Powergear X Automation Limited product catalog.

| Model | Title | Link |

|---|---|---|

| IC695ALG412 | GE Fanuc PACSystems RX3i Strain Gauge Input Module | Learn More |

| IC695NIU001 | GE Fanuc PACSystems RX3i Ethernet Network Interface Unit | Learn More |

| IC695PNS001 | GE Fanuc PACSystems RX3i PROFINET Scanner Module | Learn More |

| IC695CPU320 | GE Fanuc PACSystems RX3i CPU Module (1 GHz) | Learn More |

| IC695ALG112 | GE Fanuc PACSystems RX3i Isolated Analog Input Module | Learn More |