RX3i PLC: Powering Industrial Automation and Control Systems

The Versatile Powerhouse: GE Fanuc (Emerson) RX3i PLC in Modern Industrial Automation

The RX3i PLC is a flagship product. It was originally from GE Fanuc. Now it is part of Emerson’s suite. It is a critical asset in modern control. This platform is for demanding applications. It offers great reliability. It provides real-time processing. Its adoption is widespread. This confirms its preferred status.

Understanding the RX3i as a Programmable Automation Controller (PAC)

The RX3i is more than a PLC. It is a true PAC. It combines PLC ruggedness with advanced features. These include fast CPUs. It has deterministic Ethernet. It uses modular I/O. Its architecture is very scalable. It supports small machine control. It also runs large factory networks.

✅ Key Characteristics:

High-Speed Processing: It ensures minimal scan times.

Hot-Swap I/O: Replace modules without stopping.

Robust Communication: Supports PROFINET, Modbus, Serial.

System Integration: Handles safety and motion control.

Powering the Grid: Applications in the Energy and Utilities Sector

The energy industry needs robust control. Downtime is costly and hazardous. The RX3i manages key auxiliary functions.

It controls Balance of Plant in thermal plants. It manages boiler controls. And it handles cooling water systems. It aids substation automation. It controls wind and solar farms. Redundancy options are key here. Reliable systems cut unplanned outages.

From Wellhead to Refinery: Reliability in Oil and Gas Operations

The oil and gas sector uses the RX3i. It works in extreme environments.

Common applications include wellhead control. It manages pipeline compressor stations. It automates gas processing separation. And it integrates with SCADA systems. It works with certified safety systems. It manages remote I/O effectively.

Ensuring Public Health: Water and Wastewater Treatment Automation

Water facilities need stable control systems. Public safety depends on it. The RX3i is often chosen.

It controls raw water intake. It manages high-pressure pump stations. And it oversees aeration and sludge handling. Its longevity minimizes maintenance risks. It assures continuous, compliant operation.

Accelerating Production: High-Speed Discrete and Factory Automation

Manufacturing needs speed and synchronization. The RX3i enables higher throughput.

It is used in high-speed packaging. It controls complex assembly cells. And it integrates robotics smoothly. It connects with HMIs and VFDs. This creates adaptable production lines.

My Take: The Value Proposition of Emerson’s RX3i

The RX3i stays relevant for two reasons. It has backward compatibility. It is part of Emerson’s portfolio. This protects prior investment. It also allows for modernization.

It bridges field control and higher systems. These include DCS or MES layers. Engineers trust this workhorse. One platform serves many applications. This is its main advantage.

🔧 Technical Advantages in Implementation:

Simple configuration for redundant CPUs. It handles large tag databases well. It uses a standardized programming environment.

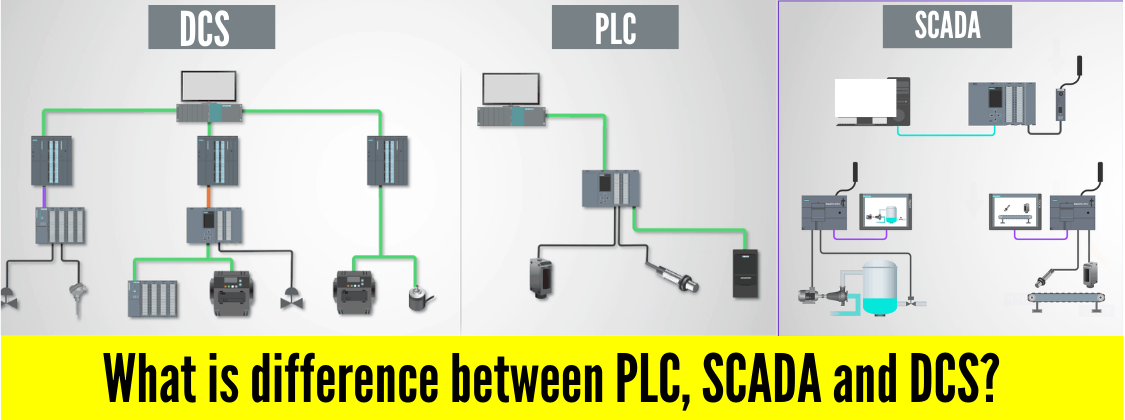

Seamless Data Exchange: Integration with SCADA and DCS Architectures

The RX3i is an intelligent I/O layer. It fits within larger supervisory architectures. It communicates with SCADA and DCS.

This allows reliable field-level control. It provides a stream of data. It supports standard industrial protocols. And it links legacy and modern equipment.

Conclusion: A Trusted Platform for Mission-Critical Control

The RX3i PLC is critically important. It combines high performance and rugged design. It has extensive communication capabilities. And t is a go-to solution for many industries. These include power generation and oil. It works in manufacturing and infrastructure. Its success proves its reliability.

FAQ: Expert Insights on RX3i Deployment

Q1: What is a common migration pitfall?

A common pitfall involves I/O configuration. The RX3i offers a migration path. Older programming was register-based. The new system is tag-based. This must be updated. Thorough testing is essential. This uses the new hardware’s full potential.

Q2: How does its PAC architecture help analytics?

The PAC architecture provides more power. It has greater memory capacity. This handles complex control logic. It manages direct, high-speed data connections. It can push data efficiently. This is great for real-time analytics. It aids predictive maintenance applications.

Q3: When should a smaller plant choose the RX3i?

Choose the RX3i for future scalability. Choose it for inherent redundancy. Use it for high-speed synchronization. Lighter-duty PLCs cannot guarantee this. It future-proofs your system. It provides better security features. And it simplifies later DCS or MES integration.

Explore Advanced Automation Solutions

Learn more about the RX3i PLC. See how it optimizes industrial processes. View specific application case studies. Please visit our website. Powergear X Automation provides expert solutions. We tailor them for complex environments.