3500/22M TDI vs 3500/92 Gateway: Modbus in Industrial Automation

The Role of the 3500/22M Transient Data Interface (TDI)

The Bently Nevada 3500/22M TDI is a critical component in the 3500 industrial automation rack. It functions primarily as the system’s interface module. This module occupies Slot 1, right next to the power supplies. Its main purpose involves configuration, data acquisition, and transferring data to host software. Specifically, the TDI gathers both steady-state and transient/waveform data. It replaces the older 3500/20 Rack Interface Module and external communications processors. The TDI communicates using Ethernet (10Base-T or 100Base-TX) and optionally fiber optics (100Base-FX). Importantly, it utilizes a proprietary “BN Host Protocol” or “TDI Protocol” over TCP/IP. Therefore, the 3500/22M TDI is fundamentally designed for communication with Bently Nevada’s dedicated monitoring and configuration software, such as System 1.

The Need for the 3500/92 Communication Gateway Module

However, when integrating the 3500 rack into plant-wide control systems, the 3500/92 Communication Gateway becomes essential. This module is specifically engineered to link Bently Nevada data with external platforms. These external systems include process-control, SCADA, DCS, and PLC systems. The 92 Gateway supports industry-standard protocols. It offers both serial (RS-232 / RS-422 / RS-485) Modbus RTU and Ethernet Modbus TCP/IP. In addition, the gateway translates the rack’s monitored values, statuses, and alarms into a Modbus-compatible format. This translation makes it straightforward for industrial automation engineers to map these critical values into their control logic.

Does the 3500/22M TDI Support Modbus Communication?

The short answer is no; the 3500/22M TDI does not inherently offer Modbus communication for integration with DCS/PLC systems. Official documentation for the 22M TDI confirms its communication is restricted to the proprietary BN Host Protocol. This protocol is strictly for communication with Bently Nevada’s own monitoring and configuration tools. There is no mention of support for standard automation protocols like Modbus RTU or Modbus TCP in the TDI specifications. System-level documentation further clarifies this distinction. It indicates that digital communications intended for process control must originate from a dedicated Communication Gateway module. Consequently, the TDI serves its vital role in high-fidelity data collection and analysis, not in plant-level control interfacing.

The Critical Requirement for DCS/PLC Integration

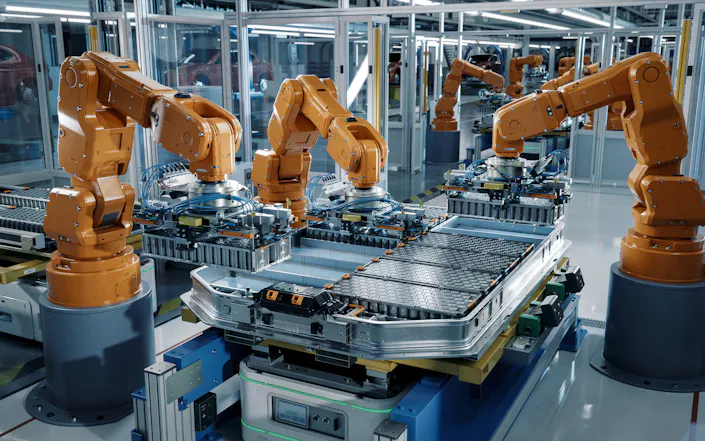

You need the 3500/92 Communication Gateway whenever you must export Bently Nevada data to a non-native system. This integration is common in modern factory automation environments.

- ✅ Export Measurements: Send vibration levels, alarms, and channel health to a DCS, PLC, or SCADA system via standard protocols like Modbus RTU or Modbus TCP.

- ✅ Real-time Trending: Perform real-time data logging, alarm forwarding, and execute control logic based on the 3500 rack data.

- ✅ Plant-wide Integration: Integrate the 3500 machinery protection system into a centralized plant automation system.

Therefore, if an organization relies solely on the 3500/22M TDI, they can only interface with the manufacturer’s software like System 1. They cannot natively send standardized Modbus data directly to a third-party PLC or DCS. According to recent studies, the integration of condition monitoring data with DCS systems significantly improves asset performance management across industries (source: MarketsandMarkets Industry Report on Industrial Control Systems).

Table: Key Differences in 3500 Communication Modules

| Module | Purpose / Role | Supports Modbus? | Typical Use-case |

|---|---|---|---|

| 3500/22M TDI | Rack Interface, Configuration, High-Speed Data Collection (transient/waveform) | No (Uses proprietary BN/TDI protocol over Ethernet/USB) | Data logging, condition monitoring, advanced waveform analysis, System 1 interface |

| 3500/92 Gateway | Exports rack values/status to external plant control/automation systems | Yes (Supports Modbus RTU and Modbus TCP) | DCS/SCADA/PLC integration, historian logging, interlocks for process control, industrial automation |

Author’s Insight: Choosing the Right Module for Industrial Automation

Powergear X Automation Comment: Many new industrial automation engineers mistakenly assume the 3500/22M TDI is sufficient for all communications. However, they soon discover this limitation when attempting to map the 3500 data into their Rockwell, Siemens, or Emerson PLCs or DCSs. The TDI’s focus on high-speed, proprietary data for advanced analysis (System 1) differs completely from the gateway’s focus on robust, standardized protocol export (Modbus). Moreover, relying on a dedicated gateway like the 3500/92 separates the machine protection function from the process control function. This design choice aligns with industry best practices, ensuring a failure in the DCS communication link does not compromise the vibration monitoring system’s integrity. To understand more about robust protocol integration in factory automation, we invite you to explore our solutions at Powergear X Automation.

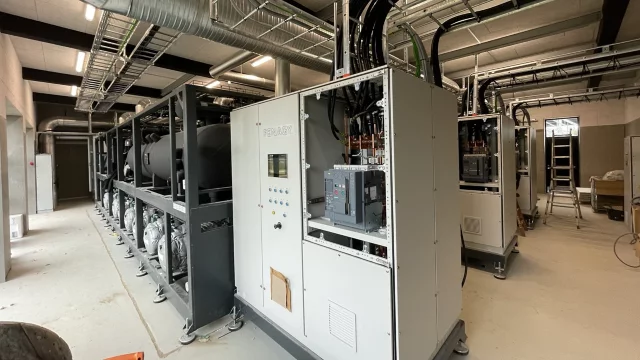

Practical Application Scenario: Maximizing Uptime

Consider a critical turbine application. The 3500/22M TDI continuously streams high-resolution vibration data to the System 1 software for deep diagnostics and predictive maintenance. Meanwhile, the 3500/92 Communication Gateway simultaneously sends essential parameters—the overall vibration level and the ‘Alert’ alarm status—to the plant’s DCS via Modbus TCP/IP. This dual setup allows plant operators to monitor immediate, actionable status from their familiar DCS console while expert reliability engineers perform detailed analysis using the System 1 platform. This strategy optimizes both operational response time and long-term asset health management.

Frequently Asked Questions (FAQ)

Q: Why can’t Bently Nevada simply integrate Modbus into the TDI to reduce hardware?

A: The TDI is engineered for high-bandwidth, proprietary communication to support advanced waveform analysis and configuration. Integrating the processing power required for a reliable, multi-client Modbus server, along with the necessary data mapping and protocol stacks, would significantly complicate the TDI’s core task and potentially compromise its performance. The dedicated 3500/92 Gateway separates these concerns, ensuring optimal performance for both high-fidelity monitoring and standard industrial control integration.

Q: If I use the 3500/92, do I still need the 3500/22M TDI?

A: Yes, you typically need both. The 3500/22M TDI performs the essential function of rack configuration and high-speed data collection from the monitoring modules. Without the TDI, you cannot configure the rack or collect the detailed transient data needed for advanced condition monitoring software like System 1. The 3500/92 Gateway only handles the translation and export of selected data points to external systems.

Q: What is the main advantage of using Modbus TCP over a proprietary protocol in automation?

A: Modbus TCP/IP is an internationally accepted, open standard protocol. Its main advantage is interoperability. It allows you to seamlessly connect the 3500 system to almost any major brand of PLC, DCS, or SCADA system (e.g., Siemens, Schneider, Honeywell, ABB) without needing special drivers or custom software. This reduces engineering time, simplifies maintenance, and promotes consistency across the entire factory automation infrastructure.