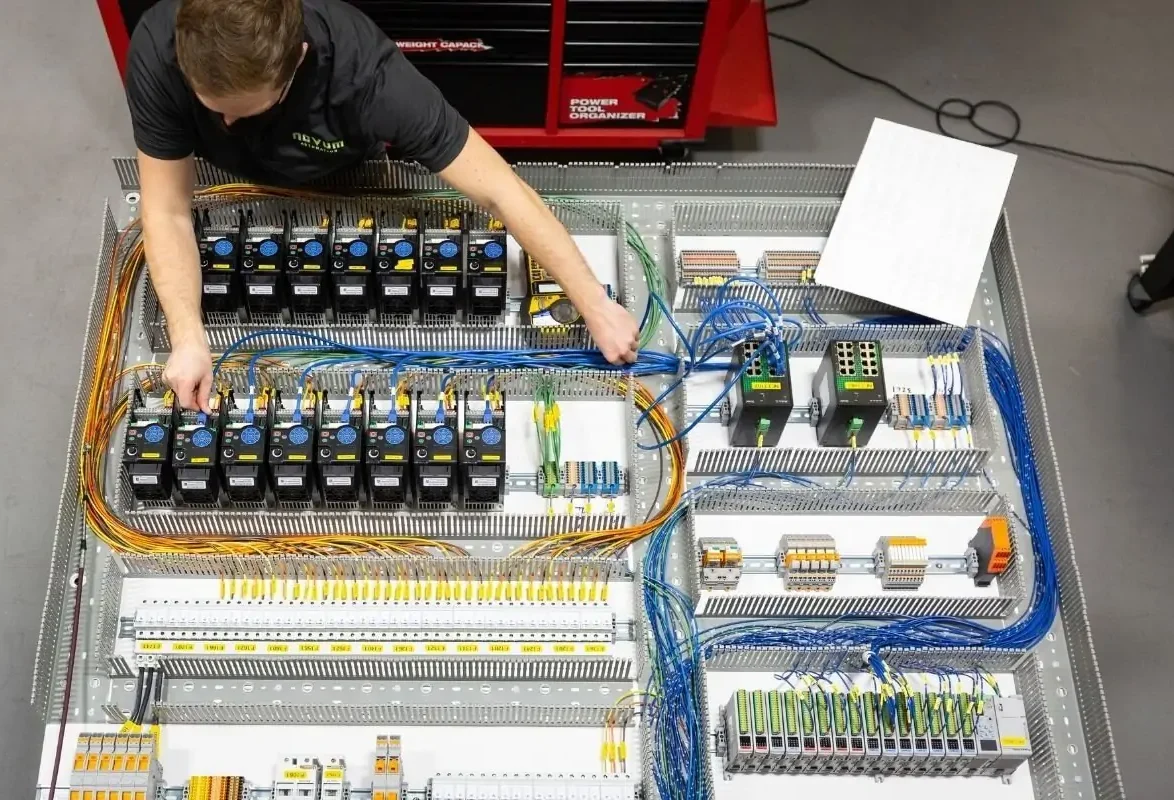

Step-by-Step Setup Guide for Allen-Bradley PowerFlex 40P AC Drives in Industrial Automation

Welcome, fellow engineers! This practical guide walks you through setting up Allen-Bradley PowerFlex 40P AC Drives, sharing hands-on insights for efficient commissioning in industrial systems.

Understanding the PowerFlex 40P: My Perspective

The PowerFlex 40P delivers exceptional balance between features and simplicity. Its sensorless vector control and compact design make it ideal for applications requiring precise speed control without encoder feedback, especially where panel space is limited.

Essential Pre-Installation Checks

Critical preparations before wiring:

- Power Verification: Confirm voltage/current ratings match supply – check nameplate to prevent damage

- Environment: Ensure clean, dry, cool location – avoid dust, moisture and excessive heat

- Motor Compatibility: Verify motor HP, voltage, and current ratings match drive capabilities

Wiring the PowerFlex 40P: Practical Tips

Power Wiring (L1/L2/L3 to T1/T2/T3):

Use oversized wires for better current handling and heat dissipation. Connect AC power to L terminals and motor to T terminals.

Control Wiring:

- Separate control wires from power cables to prevent noise interference

- Always use shielded cables for analog signals

Grounding Protocol:

Connect ground terminal directly to earth ground – critical for safety and noise reduction.

Basic Configuration and Parameter Setup

Initial Power-Up:

After securing connections, apply power – keypad should illuminate.

Motor Data Entry:

Set these parameters precisely from motor nameplate:

- P031 [Motor NP Volts]

- P033 [Motor NP Amps]

- P034 [Motor NP Freq]

- P035 [Motor NP RPM]

Control Source Selection:

Configure A041 [Start Source A] for keypad (initial testing), digital inputs (PLC), or analog input.

Speed Reference Scaling:

For analog inputs:

- Set P038 [Analog Input 1 Sel]

- Scale with A051 [Anlg In1 Scale Lo] and A052 [Anlg In1 Scale Hi]

Advanced Considerations and Troubleshooting

Auto-Tune Optimization:

Execute P040 [Motor Auto Tune] to measure motor characteristics for peak performance.

Acceleration/Deceleration:

Balance P044 [Accell Time 1] and P045 [Decel Time 1] to avoid trips or sluggish operation.

Fault Management:

Interpret common codes – address root causes of overcurrent, overvoltage, and ground faults.

Preventive Maintenance:

- Keep cooling fins dust-free

- Regularly check terminal tightness

Conclusion: Empowering Your Industrial Automation

Mastering PowerFlex 40P setup requires attention to wiring detail, accurate parameter entry, and proactive troubleshooting – essential skills for robust automation systems.

Ready to upgrade your industrial control systems? Click here to explore Allen-Bradley PowerFlex 40P AC Drives and automation solutions from Powergear X Automation Limited.