ABB DO810 Technical Guide: Contact Ratings and Solenoid Loads

Analyzing the DO810 Contact Ratings for Inductive Loads

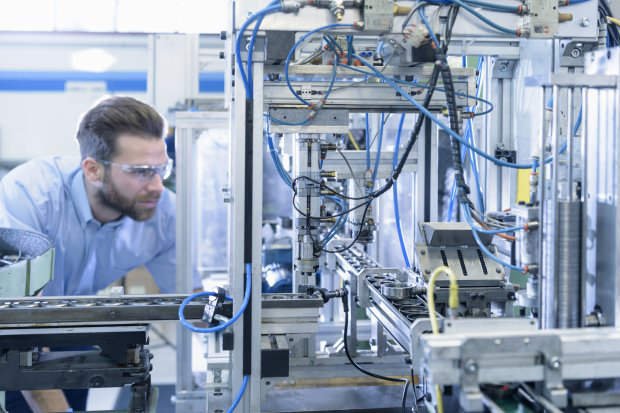

The ABB DO810 serves as a cornerstone for isolated switching within the S800 I/O family. While its technical datasheet provides a high-level overview, successful deployment in harsh industrial environments requires a deeper understanding of inductive load dynamics. This guide explores how to maximize module lifespan and ensure system stability in DCS and PLC architectures.

The DO810 module carries a nominal rating of 2 A at 250 VAC or 30 VDC. However, these figures primarily describe resistive loads. In industrial automation, most field devices, such as solenoid valves, are highly inductive. Inductive loads create significant inrush current during startup and high-voltage flyback during shutdown. Powergear X Automation experts recommend derating these contacts by at least 50% for inductive applications to prevent premature pitting.

The Impact of Mechanical Relay Cycles on Maintenance

Unlike solid-state outputs, the DO810 utilizes electromechanical relays to provide superior galvanic isolation. This physical separation protects the DCS backplane from field-side electrical noise. However, mechanical components have a finite operational life, typically between 10^5 and 10^6 cycles. Consequently, engineers should avoid using this module for high-frequency pulsing or Pulse Width Modulation (PWM). Frequent switching will lead to mechanical fatigue and contact welding.

Why External Surge Suppression is Mandatory

The DO810 lacks integrated internal surge suppression for its relay outputs. When an inductive coil de-energizes, the collapsing magnetic field generates a massive voltage spike. Without protection, this energy arcs across the relay contacts, vaporizing the metal surface. Therefore, you must install external flyback diodes for DC circuits or RC snubbers for AC circuits. This simple addition can extend the life of your DO810 module by several years.

Practical Field Advice for Industrial Installations

Experience in refinery and chemical plant settings shows that physical installation quality dictates long-term reliability. Loose connections often cause localized heating, which damages the module’s plastic housing and terminal blocks. Powergear X Automation suggests the following technical best practices:

Utilize high-quality ferrules on all stranded field wiring.

Implement a routine maintenance schedule to check terminal tightness.

Ensure the cabinet temperature remains within the specified operating range.

Use interposing relays for any load exceeding 1 A steady-state.

Powergear X Automation Commentary on Industry Trends

In modern factory automation, the trend is shifting toward “smart” I/O with built-in diagnostics. While the DO810 is a reliable workhorse, many plants now integrate interposing relays as a sacrificial layer. This strategy is economically sound. It is far more cost-effective to replace a $15 plug-in relay than to replace a $500 DCS output module and face unplanned downtime. We believe the DO810 remains a top choice for isolation, provided engineers respect its physical limits.

Application Scenario: Solenoid Bank Control

In a typical oil and gas manifold application, the DO810 manages a bank of 24 VDC solenoid valves. To ensure 99.9% uptime, the design includes:

1N4007 Diodes across each solenoid coil to suppress spikes.

External Fusing for each channel to protect against field shorts.

Shielded Cabling to reduce EMI interference with neighboring analog signals.

Frequently Asked Questions (FAQ)

How can I identify if my DO810 relay contacts are beginning to fail?

Look for “stuck” outputs where the LED is off but the circuit remains closed, or “high-resistance” faults where the LED is on but the valve fails to actuate. If you notice intermittent operation that resolves temporarily after a light tap on the module, the contacts are likely pitted and require replacement.

Should I choose the DO810 or a solid-state DO818 module?

The choice depends on your load. Choose the DO810 for mixed voltage levels and high isolation requirements. Opt for a solid-state module like the DO818 if you need high-speed switching or have very low-power loads that might not “wet” a mechanical relay contact effectively.

What is the most common mistake when ordering replacement modules?

Many buyers fail to check the version of the MTU (Module Termination Unit) currently installed. Ensure your existing baseplate is compatible with the DO810’s physical keying to avoid installation delays during a turnaround.

For more technical insights and high-quality automation components, visit Powergear X Automation to explore our full range of industrial solutions.