Testing 3300 XL 8mm Proximity Probes with an Oscilloscope

Understanding the 3300 XL Proximity Probe System

The 3300 XL 8mm proximity probe is a crucial component in industrial automation. These probes are essential for measuring shaft position, vibration, and speed. They are widely used in factory automation and control systems. A typical system includes the probe, an extension cable, and a proximity probe transducer. This system provides critical data for monitoring rotating machinery. Understanding its function is the first step to effective troubleshooting.

Why an Oscilloscope is Your Best Tool

An oscilloscope is a powerful diagnostic tool. It visualizes the probe’s output signal. This lets you see dynamic changes in real-time. Therefore, you can pinpoint issues that a simple multimeter cannot. An oscilloscope shows signal noise, voltage drift, and proper waveform shape. This is vital for accurate diagnostics. Without an oscilloscope, you might miss subtle signal problems.

Step-by-Step Guide to the Testing Process

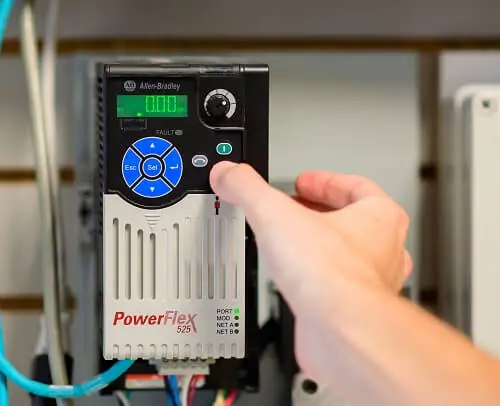

First, connect the probe system to a power supply. The 3300 XL probe requires a DC power source. Next, connect the oscilloscope to the transducer output. Use a BNC cable for a secure connection. Set the oscilloscope to DC coupling. The voltage scale should be appropriate for the expected output range. Move a metallic target in front of the probe tip. Observe the voltage trace on the oscilloscope screen. The voltage should change smoothly as the target moves. This confirms the probe is working correctly. A steady voltage indicates a fault.

Interpreting the Oscilloscope Waveform

A healthy proximity probe signal is a smooth, clean DC voltage. This voltage varies based on the target distance. As the target moves closer, the voltage drops. Conversely, the voltage rises as the target moves away. A noisy or erratic waveform suggests a problem. The issue could be electrical interference or a damaged cable. For example, a wavy pattern might mean improper grounding. Furthermore, a sudden voltage drop indicates a fault in the probe itself or the extension cable.

Common Problems and Troubleshooting Tips

Several issues can affect 3300 XL probe performance. Common problems include mechanical damage or incorrect gap settings. A damaged probe tip will produce a faulty signal. An improper mounting gap also leads to inaccurate readings. For instance, if the probe is too far from the target, the output signal is weak. Checking for loose connections is also a critical step. Moreover, environmental factors like temperature or humidity can impact sensor performance. Therefore, always consider the operating environment during your analysis.

My Take on Industrial Monitoring

In my experience, proactive testing is key to reliable industrial automation. While some companies rely on reactive maintenance, a predictive approach saves money. Using tools like oscilloscopes for routine checks prevents catastrophic failures. The 3300 XL system is a Bently Nevada standard, known for its reliability. However, even the best equipment needs proper maintenance. My advice is to invest in good diagnostic tools and training. This ensures your PLC and DCS systems receive accurate data. Ultimately, this practice enhances operational safety and efficiency.

Solutions and Applications in the Field

Powergear X Automation Limited specializes in providing robust solutions for rotating machinery. Our products are designed to integrate seamlessly with your existing control systems. We offer a full range of sensors, including the 3300 XL series, along with expert support. For more information on our solutions and to find the right products for your application.

| Model | Title | Link |

|---|---|---|

| 330105-02-12-30-02-CN | Bently Nevada Reverse Mount Probe | Learn More |

| 330105-02-12-30-12-00 | 3300 XL 8 mm Reverse Mount Probe | Learn More |

| 330105-02-12-15-12-05 | 3300 XL 8 mm Proximity Probe | Learn More |

| 330105-02-12-05-12-05 | 3300 XL 8 mm Proximity Probe | Learn More |