A6110 Shaft Vibration Monitor: API 670 Protection for Critical Assets

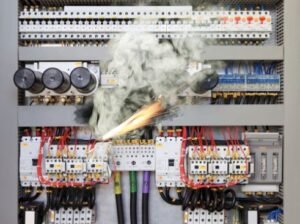

The A6110: Essential Protection for Rotating Equipment

Critical rotating machinery demands reliable protection. The A6110 Shaft Relative Vibration Monitor delivers this essential safeguard. This single-slot module fits seamlessly into existing AMS 6500 systems. Moreover, it rigorously adheres to stringent API 670 standards. It uses advanced non-contact eddy current sensors. Consequently, the A6110 accurately measures shaft relative vibration. Early detection of issues prevents catastrophic machine failures. This proactive approach minimizes costly downtime in industrial automation settings.

Precision Measurement and Technical Edge

The A6110 boasts impressive technical specifications. It features two independent input channels. Eddy current displacement sensors provide the core input data. This setup ensures high-precision monitoring. The wide frequency range, from 1 Hz to 2000 Hz, captures all relevant vibration data. Powering the module requires a standard 24 VDC supply. Furthermore, it operates reliably within a 0° to 65°C temperature range. Compliance with both API 670 and DIN standards confirms its superior quality and dependability.

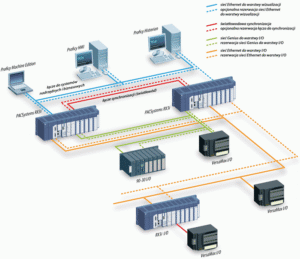

Seamless Integration with Control Systems

Effective communication is crucial for modern control systems. The A6110 excels in this area. It provides 4-20 mA current outputs for easy PLC or DCS integration. Additionally, 0-10 VDC voltage outputs offer proportional vibration signals. For configuration, an RS-232 interface is standard. Critically, ModBus TCP/IP ensures robust data communication across the network. Buffered raw signal outputs are available for detailed diagnostic analysis. These features make it a versatile component in any factory automation architecture.

A Hot-Swappable Solution for Maximum Uptime

Downtime severely impacts productivity. Therefore, the A6110 features a valuable hot-swappable design. Technicians can replace the module without system shutdown. This capability guarantees maximum operational uptime. The monitor typically protects equipment like steam and gas turbines, high-speed compressors, and large sleeve-bearing pumps. In addition, it supports sensor installations up to 300 meters away. This flexibility is vital for extensive industrial facilities. The A6110 embodies a commitment to continuous, reliable operation.

Expert Insight: Enhancing Reliability and Predictive Maintenance

The adherence to API 670 is a non-negotiable standard for critical rotating equipment. The A6110 meets this industry benchmark, confirming its reliability and precision. I believe its integration of ModBus TCP/IP is particularly significant. This modern protocol facilitates true predictive maintenance strategies. It allows maintenance teams to transition from reactive to proactive intervention. This shift significantly reduces unexpected shutdowns and extends equipment lifespan. Investing in the A6110 means investing in long-term asset health.

Solution Scenario: Turbine Generator Protection

Consider a power generation facility using a large steam turbine. The A6110 is the ideal protection solution here. Two independent eddy current probes mount at the turbine shaft bearings. They continuously measure relative shaft movement. The module instantly transmits data via ModBus TCP/IP to the plant’s DCS. If vibration levels rise, the control system triggers an alarm or shutdown. This immediate response prevents severe damage to the turbine and generator. The A6110 ensures the integrity of this high-value, critical asset.

Discover the robust protection and seamless integration of the A6110 monitor.

Click here to explore how Powergear X Automation Limited can integrate this essential technology into your critical machinery protection strategy.