Smart Motor Controllers: The Strategic Shift for Modern Industrial Automation

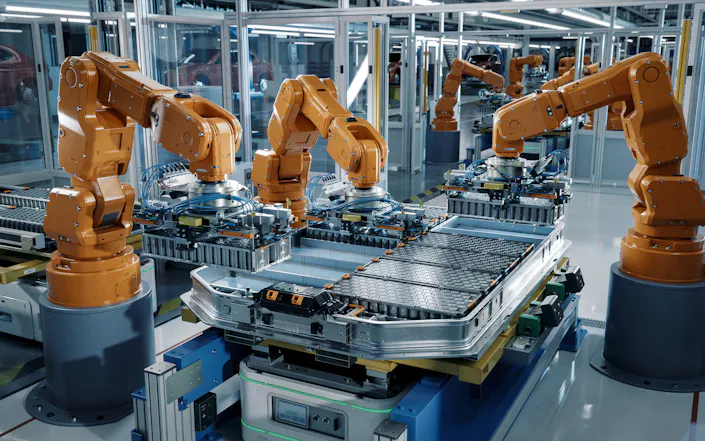

The decision between using a smart motor controller and a traditional starter is far more than a simple technological upgrade; it is a strategic choice impacting facility uptime, energy efficiency, and long-term operating costs. Traditional motor starters are fundamentally simple devices that only handle starting and stopping the motor. However, smart motor controllers introduce advanced functionalities that deliver greater control, deeper insights, and significant efficiency improvements. From real-time diagnostics to remote firmware capabilities, these devices are fundamentally changing how manufacturers approach motor asset management. Let’s examine the decisive advantages and understand why forward-thinking facilities are now making this critical transition in industrial automation.

Remote Updates Ensure System Agility and Security

Traditional starters are inherently static. Once installed, they cannot adapt to evolving operational demands or emerging security threats. Any necessary upgrade or fix requires a physical intervention, often leading to costly downtime or even complete unit replacement. Smart motor controllers, conversely, embrace dynamic adaptation. Drives like the Allen-Bradley PowerFlex 755T, Schneider Electric Altivar Process, and Danfoss FC 302 support Over-the-Air (OTA) firmware updates. This capability keeps your control systems current with the newest features, essential security patches, and performance enhancements—all without needing a technician onsite.

Faster Adaptation: Quickly respond to new regulatory or production requirements.

Reduced Maintenance: Minimize costs associated with manual service calls.

Continuous Improvement: Consistently enhance energy efficiency and control capabilities.

Commentary from Powergear X Automation: We consistently see remote update capability as a major differentiator. For busy plants with complex control systems like PLC or DCS, updating drives without interrupting production offers massive operational savings. Click here to learn more about our remote drive management solutions: https://www.powergearx.com/

Proactive Voltage Monitoring Extends Motor Lifespan

Unexpected power quality issues, such as sharp voltage fluctuations or phase imbalances, pose a significant risk to industrial motors. Traditional starters offer no real-time protection, leaving valuable motor assets vulnerable to catastrophic failure. Smart controllers, by contrast, actively and continuously monitor voltage thresholds. If the system detects a deviation from nominal parameters, it initiates an automatic, protective response. This proactive defense mechanism can trigger a controlled load shedding, an immediate but safe motor shutdown, or an operator alert. Drives such as the Siemens SINAMICS G120, ABB ACS580, and Schneider Altivar 71 even allow operators to customize precise trip points based on their specific application needs. As a result, this feature not only extends the motor’s functional lifespan but also dramatically improves the stability of the entire factory automation system, especially in unstable utility environments.

Electrical Parameter Monitoring for Predictive Maintenance

A smart motor controller functions as the motor’s dedicated health monitor, providing deep, actionable data. Unlike standard starters, which provide zero operational feedback, smart controllers meticulously track and log key parameters. They measure essential metrics, including:

Voltage, current, and true power consumption

Frequency, power factor, and load trends

Energy usage over time

This constant data stream is foundational for effective predictive maintenance. Teams can analyze real-world data to identify potential motor fatigue or inefficiencies. For example, drives like the ABB ACS880 and Schneider Altivar Process feature integrated metering tools and historical data logs. Therefore, maintenance teams can identify energy waste or impending overloads before they escalate into disruptive and costly shutdowns.

Adaptive Control Drives Superior Energy Efficiency

Traditional starters operate using fixed, conservative parameters. Whether a motor is lightly loaded or operating at full capacity, it receives the same fixed voltage and speed setting. This results in excessive mechanical wear, wasted energy, and a shortened lifespan. Smart motor controllers utilize sophisticated adaptive control algorithms to dynamically adjust voltage, speed, and torque in real-time. They continuously evaluate dynamic factors like:

Instantaneous load variation

Ambient operational temperature

Precise process flow requirements

The outcome is exceptionally smooth operation, reduced mechanical stress on the motor, and demonstrably lower electricity expenses. Noteworthy examples of this technology include: Danfoss VLT FC 302 (for precision efficiency using dynamic flux control) and Allen-Bradley PowerFlex 755T (for intelligent speed/torque control across variable conditions). This is a key principle of modern industrial automation.

Seamless Industrial Communication for Connected Operations

Smart motor controllers are deliberately designed for the connected manufacturing environment. They communicate using standard industrial languages, facilitating direct integration into your wider DCS or PLC framework. Common protocols supported include:

Ethernet/IP

PROFINET

Modbus TCP

This connectivity allows controllers to feed vital, real-time insights—from motor health status to immediate energy consumption data—directly into your SCADA, HMI, or Manufacturing Execution System (MES). In contrast, traditional starters operate in informational darkness. They have no network connection, provide no feedback, and offer no integration into automated systems. Devices like the Siemens SINAMICS G120 and PowerFlex 700 series enable powerful features like automatic load balancing and predictive alerts, which are non-negotiable for today’s data-centric factories.

Fault Logging Simplifies Troubleshooting and Maintenance

Troubleshooting a failure related to a traditional starter is often a frustrating process of guesswork and delayed reaction. The issue is usually only discovered after it has caused a major operational fault or physical damage. Smart motor controllers eliminate this reactive maintenance trap. They feature robust, integrated diagnostic capabilities, including:

Automatic and time-stamped fault logging

Detailed event history and trend recording

Built-in self-diagnostics

This data makes identifying and diagnosing recurring issues significantly faster and more accurate. Furthermore, the logged history can be crucial for verifying warranty claims or supporting the scheduling of truly proactive, condition-based maintenance. As a result, operations experience fewer unexpected breakdowns and spend less time on costly reactive repairs.

The Strategic ROI: Why Smart is the New Standard

Adopting smart motor controllers delivers a clear Return on Investment (ROI). These devices are essential for future-proofing your operations because they:

Protect assets from damaging electrical faults.

Cut energy consumption through dynamic, adaptive control.

Simplify maintenance with deep, real-time diagnostic data.

Enable remote management via network-enabled firmware updates.

Extend the useful life of your motor fleet.

Author’s Comment: The shift is driven by economics. While the initial cost is higher, the total cost of ownership (TCO) for a smart controller is lower over a 5-year period due to energy savings and massive reduction in unplanned downtime. According to a MarketsandMarkets report, the global motor control center market is moving toward smart solutions, validating this strategic direction.

Application Scenario: Pump and Fan Systems

Consider a water treatment facility using a large pump system (a typical industrial automation application).

Traditional Starter: The pump runs constantly at 100% speed, even when only 60% flow is needed, wasting significant energy and causing unnecessary wear on mechanical seals.

Smart Motor Controller (e.g., Danfoss VLT): The drive uses a PID loop based on the pressure sensor feedback. It automatically and smoothly ramps the pump speed up or down to precisely match the current flow demand. This dynamic adjustment can lead to a 20-40% reduction in electricity consumption and drastically extends the Mean Time Between Failures (MTBF) for the pump system components.

Frequently Asked Questions (FAQ)

Q1: How much time and money can I realistically save by switching from a starter to a smart drive?

A: The savings are typically two-fold: energy and maintenance. The US Department of Energy often cites that Variable Frequency Drives (VFDs), a type of smart controller, can save 20-50% of the energy consumed by centrifugal pumps and fans by running them slower when full capacity isn’t needed. Moreover, the predictive maintenance data drastically reduces reactive repair costs and unexpected production losses, which can often be 5-10 times the cost of the repair itself.

Q2: Will integrating a smart motor controller complicate my existing PLC or DCS programming?

A: Generally, no. While traditional starters use basic hardwired I/O, smart controllers use industrial Ethernet (like PROFINET or Ethernet/IP). Modern PLC and DCS systems have pre-built Add-On Instructions (AOIs) or function blocks for major drive brands (Allen-Bradley, Siemens, Schneider). This simplifies the programming process and allows you to access hundreds of diagnostic parameters with just a few data tags, which is far simpler than managing dozens of physical wires.

Q3: Is it better to upgrade an old motor or install a smart controller with my existing motor?

A: If your motor is in good condition, you can typically install a smart motor controller (VFD) immediately for instant efficiency gains. However, for maximum efficiency and longevity, especially with drives, we recommend upgrading to an Inverter Duty (NEMA Premium Efficiency) motor. These newer motors are thermally and electrically designed to handle the high-frequency switching and harmonics produced by the smart controller, ensuring the longest lifespan for both components.

Need a Recommendation?

If your facility is still reliant on traditional motor starters, the time to upgrade is now. We stock and support top-tier smart motor controllers from every major brand—Allen-Bradley, Siemens, Schneider Electric, ABB, and more. Our experts can help you select the ideal drive tailored to your specific application and system architecture.

Contact us today—let us help you future-proof your industrial automation operations.

Leave a Comment

Your email address will not be published. Required fields are marked *