Product details

Overview

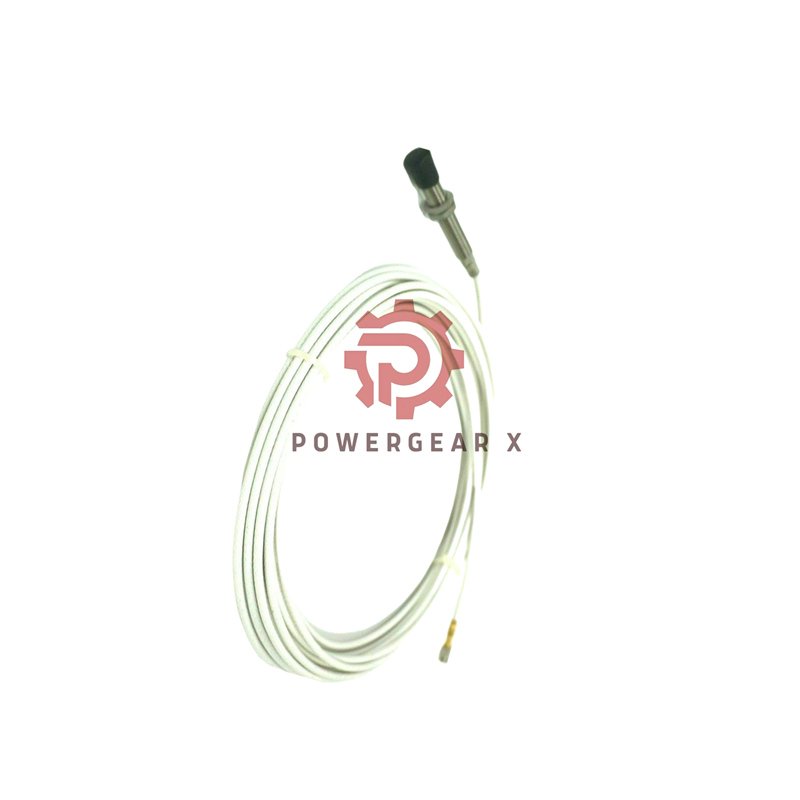

The 111-412-000-013-A2-B1-E010-F0-G000-H05 proximity measuring system is a high-performance solution from Meggitt (Vibro-Meter) designed for precise non-contact vibration and position monitoring in hazardous environments. Its Ex-certified design ensures safe operation and long-term reliability for industrial machinery.

Product Tree — Suffix Breakdown

- 111-412-000-013: Base proximity measuring system from the Vibro-Meter® product line.

- A2: Explosive Ex i environment rating for hazardous areas.

- B1: M10 × 1 body thread ensuring strong mechanical mounting.

- E010: 1.0 m ±100 mm integral cable length for flexible installation.

- F0: No optional protection.

- G000: No flexible hose protection.

- H05: 5 m total system length from transducer to conditioner.

Key Features and Benefits

- Non-contact eddy-current measurement for vibration and shaft position monitoring.

- API 670 compliant, supporting condition monitoring and protection systems.

- Ex-certified for use in potentially explosive atmospheres.

- Temperature-compensated design ensures consistent accuracy under varying conditions.

- Compatible with VM600Mk2, VM600, and VibroSmart® systems.

- Available in 1, 5, or 10 m configurations for flexible installation.

Technical Specifications

- Brand and Model: Meggitt Vibro-Meter 111-412-000-013.

- Measurement Range: 2 mm or 4 mm, high accuracy range options.

- Frequency Response: DC to 20 kHz (−3 dB) for wide dynamic response.

- Temperature Range: −40 to +180 °C continuous, short-term up to +220 °C.

- Environmental Rating: IP68 for sensor head and integral cable.

- Output Type: Voltage or current output with built-in short-circuit protection.

- Construction: Ø8 mm wire coil, Torlon tip, stainless steel AISI 316L body with epoxy encapsulation.

- Cable Type: FEP-covered 70 Ω coaxial cable (Ø3.6 mm) with self-locking miniature connectors.

- Vibration Resistance: 5 g peak (10–500 Hz) per IEC 60068-2-26.

- Shock Resistance: 15 g peak, 11 ms half-sine per IEC 60068-2-27.

- Signal Source: Requires high-frequency power from an IQS900 signal conditioner.

Installation Guide

- Thread sensor body securely into mounting point and hand-tighten connector until locked.

- Calibrate the sensor tip distance using a precision shim for accurate gap measurement.

- Route cables away from high-temperature areas and secure to prevent abrasion.

- Follow Ex installation standards for hazardous zones with proper grounding.

- Verify operation with the IQS900 conditioner and record baseline readings.

Packaging List

- 1 × 111-412-000-013-A2-B1-E010-F0-G000-H05 proximity transducer with integral cable.

- 1 × Quick-start installation guide.

- 1 × Protective tip cover or sleeve for transport.

- Shipping via FedEx,

UPS, or

DHL.

Applications

- Ideal for shaft vibration and position monitoring on turbines and compressors.

- Perfect for API 670 machinery protection applications.

- Suitable for continuous machine condition monitoring and diagnostic systems.

Frequently Asked Questions (FAQ)

- Q: What are the available measurement ranges?

- A: The system supports 2 mm or 4 mm ranges depending on application needs.

- Q: Which conditioner works with this model?

- A: The 111-412-000-013 operates with an IQS900 signal conditioner or equivalent.

- Q: Is it suitable for hazardous zones?

- A: Yes, it is Ex i certified for safe use in explosive areas.

Contact & Ordering

- For inquiries, email sales@powergearx.com or WhatsApp

+86 18030005825. - Specify model 111-412-000-013 and suffix configuration when ordering.

Copyright © 2025 Powergear X Automation Limited. All rights reserved.

Original Source: https://www.powergearx.com/

There are no reviews yet.