Product details

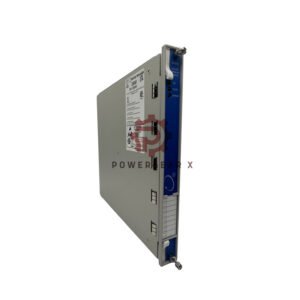

Bently Nevada 3500/50M-01-00 Tachometer Module

- Manufacturer: Bently Nevada

- Model No.: 3500/50M-01-00 286566-02

- Type: Tachometer Module

- Origin: Made in U.S.A

- Warranty: 12 months

- Shipping: FedEx, UPS, DHL

Technical Highlights

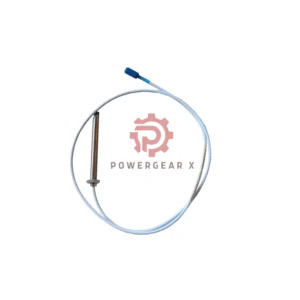

- Accepts up to 2 proximity or magnetic pickup signals

- Input range: +10.0 V to -24.0 V

- Input impedance: 20 kΩ (standard), 40 kΩ (TMR)

- Power use: 5.8 W typical

- Transducer supply: 24 Vdc, 40 mA per channel

- Recorder output: +4 to +20 mA, isolated, 100 ms update

- Output impedance: 550 Ω

- Resolution: 0.3662 µA per bit ±0.25% room temp

- Max speed: 99,999 rpm | Max frequency: 20 kHz

- Accuracy: ±0.1 rpm under 100 rpm | ±1 rpm up to 10,000 rpm

- Alarm delay: Adjustable 1–60 s (Alarm 1) / 0.1–60 s (Alarm 2)

- Size: 241.3 × 24.4 × 241.8 mm | Weight: 0.82 kg

Product Advantages

- Fast 100 ms update for real-time monitoring

- Stable RPM accuracy across full range

- Supports redundant rack systems

- Short-circuit & ESD protected buffered outputs

- Works with proximity probes or magnetic pickups

- Supports up to 255 events/rev for complex shafts

- Software configurable alarms and thresholds

- Low error rate over wide temperature range

- Fully compatible with 3500/22M and 3500 software suite

Module Compatibility

- 3500/22M Module Firmware 1.70+

- 3500/01 Config Software 4.20+

- 3500/02 Data Acquisition Software 2.52+

- 3500/03 Display Software 1.52+

- 3500/50M Firmware 5.30+

- Not compatible with 3500/20

Suffix Information

- I/O Module Type: 01 = Internal Terminations

- Agency Approval: 00 = None

Environmental Specs

- Operating Temp: -30°C to +65°C

- Storage Temp: -40°C to +85°C

- Humidity: 95% non-condensing

Certifications

- FCC Part 15 compliant

- EMC Directive 2014/30/EU

- EN 61000-6-2 / EN 61000-6-4

- LV Directive 2014/35/EU | EN 61010-1

- RoHS 2011/65/EU

- Maritime: DNV GL & ABS Certified

FAQ

- Q: How many channels does the 3500/50M handle?

A: It supports two independent transducer inputs per module. - Q: Can I use magnetic pickups with this module?

A: Yes, but restrictions apply. Check transducer type limits before installation. - Q: What software version is needed for setup?

A: Requires 3500/01 Configuration Software version 4.20 or later. - Q: How often should the tachometer module be calibrated?

A: Typically every 12–18 months depending on vibration conditions. - Q: Does it support redundancy or hot-swap operation?

A: Yes, the module can work with redundant power and supports live replacement with system care.

Contact Information

- Inquiries: sales@powergearx.com

- WhatsApp: +86 18030005825

Copyright © 2025 Powergear X Automation Limited. All rights reserved.

Original Source: https://www.powergearx.com/

Partner: Ubest Automation Limited

There are no reviews yet.