Product details

Product Snapshot

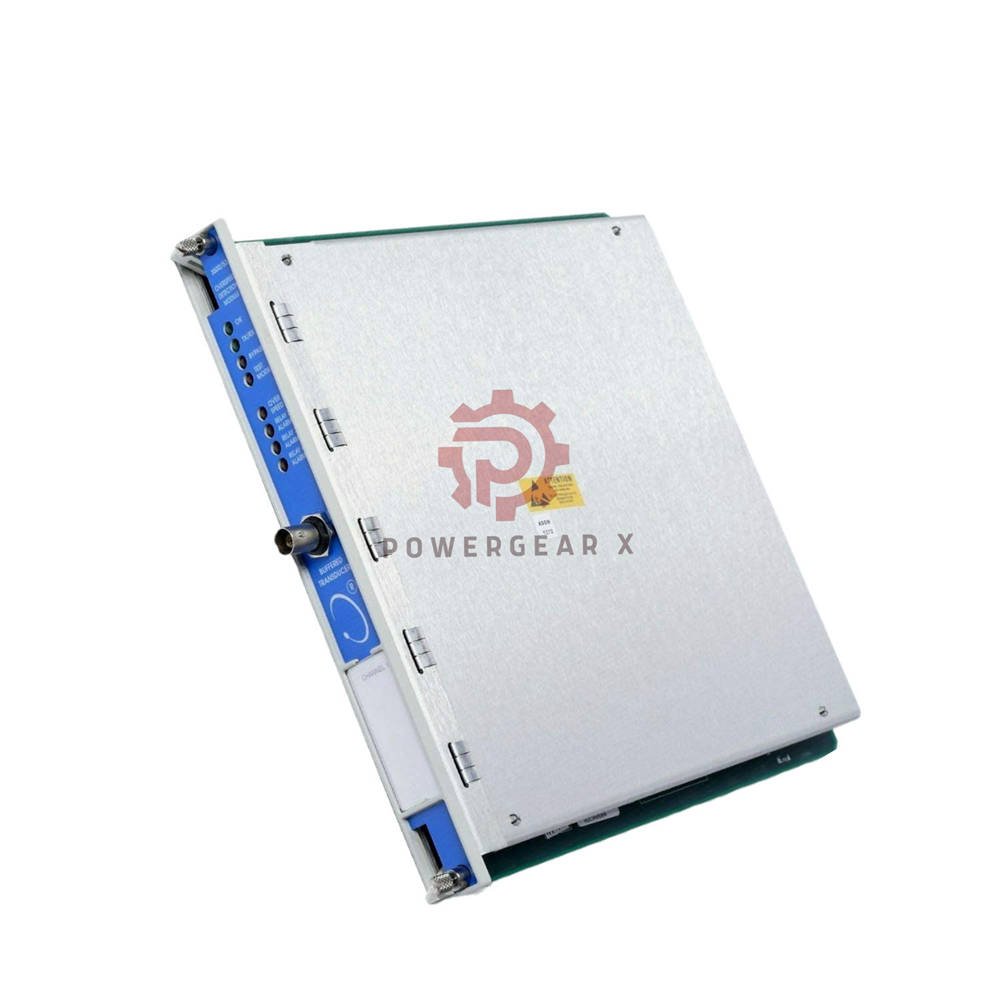

- Brand: Bently Nevada

- Model: 3500/53-03-00

- System Type: Electronic Overspeed Detection

- Series: 3500 Rack Platform

- Built for fast overspeed trip protection

- Designed for turbines and critical rotating assets

- Works with probe and magnetic pickup sensors

- Industrial safety grade design

- Made in U.S.A

- Series link:

3500/53 Overspeed Modules

Model Code Tree and Configuration Breakdown

- Order Code: 3500/53-03-00

- ├─ Base Unit:

3500/53

Electronic overspeed detector - ├─ A = Channel Option

- │ └─ 03 = Three channel system

- ├─ B = Agency Approval

- │ └─ 00 = No agency approval

- └─ Rack based modular structure

Main Protection Functions

- Monitors shaft speed for trip events

- One sensor input per channel

- Supports multi channel voting logic

- Fast relay trip response

- Front LEDs show health and alarm state

- Buffered signal output for test use

- Built in bypass and test mode

Input and Sensor Details

- Single transducer input per channel

- Input range +10 V to −24 V

- Internal signal limiting protection

- Input impedance 20 kΩ

- Sensor power −24 Vdc, 40 mA max

- Supports these probe types

- ├─ 3300 8 mm Proximitor

- ├─ 3300 16 mm HTPS

- ├─ 7200 series 5 to 14 mm

- ├─ 3300 RAM Proximitor

- └─ Magnetic pickups

Outputs and Relay Features

- SPDT relays with epoxy seal

- Arc suppressors installed as standard

- Selectable energized state per relay

- Max switched current 5 A

- Max switched voltage 30 Vdc or 250 Vac

- Max switched power 120 Wdc or 600 VAac

- Contact life 100,000 operations typical

- Buffered coax output on front panel

- Buffered output impedance 550 Ω

- Recorder output 4 to 20 mA

- Recorder load 0 to 600 Ω

- Current output update about 100 ms

- Resolution 0.3662 µA per bit

Front Panel Indicators

- OK LED shows module healthy state

- TX/RX LED shows rack communication

- Bypass LED shows bypass active

- Test Mode LED shows test status

- Alarm LEDs map to relay alarms

Power and Consumption

- Typical module use 8.0 watts

- Rack powered design

- No external power brick needed

Environmental Limits

- Operating −30 °C to +65 °C

- Storage −40 °C to +85 °C

- Humidity 95 percent non condensing

- Good noise resistance in rack system

Mechanical and Slot Rules

- Monitor size 241.3 × 24.4 × 241.8 mm

- Monitor weight about 0.82 kg

- I/O module depth 99.1 mm

- I/O module weight about 0.45 kg

- Front slot need one per channel

- Rear slot need one per channel

Installation and Setup Notes

- Install each channel in one front slot

- Match each with rear I/O module

- Check probe gap and wiring first

- Verify relay logic before run

- Use test mode for trip checks

- Record trip setpoints in project file

Service and Maintenance Strengths

- Front buffered output helps testing

- LEDs speed up fault finding

- Module swap is fast in rack

- No field calibration needed often

- Stable long term drift control

Typical Use Cases

- Steam turbine overspeed trip

- Gas turbine protection loops

- Compressor driver safety

- Critical generator trains

- High value rotating lines

Supply, Warranty, Shipping

- Standard warranty 12 months

- Tested before shipment

- Ship by FedEx, UPS, or DHL

- Anti static safe packing

- Global delivery support

FAQ

- How is this different from normal speed monitors

- It focuses on trip protection, not only measurement.

- Can I mix probe and magnetic sensors

- Yes. Each channel accepts either type.

- How do I test relay trips safely

- Use built in test mode before real startup.

- What should I check before buying

- Confirm channel count and rack free slots.

- What support comes with purchase

- Includes 12 month warranty and courier shipping.

Contact and Ordering Help

- Email:

sales@powergearx.com - WhatsApp:

+86 18030005825 - Product family:

3500/53 series page

Original Source: https://www.powergearx.com/

Partner: PLCDCS HUB Limited

Copyright © 2025 Powergear X Automation Limited. All rights reserved.

Kevin Lawson –

We selected the Bently Nevada 3500/53-03-00 overspeed module for a turbine protection project. The unit was brand new and exactly as specified. PowerGearX handled the order efficiently and shipped it quickly, which was crucial for our commissioning timeline. After installation, the overspeed system performed reliably during testing and startup. This module adds an essential layer of safety for our rotating equipment. The overall buying experience was smooth, and the technical support team was knowledgeable and responsive. A solid solution for high-risk applications.