Product details

Product Description

- Bently Nevada 3500/42-01-02 is a high precision vibration monitor for critical machines.

- It belongs to the 3500/42M monitoring platform.

- The module processes proximity, velocity, and acceleration signals in real time.

- It supports up to four sensor channels per monitor.

- The design improves machine protection and early fault detection.

- It fits turbine, compressor, and pump monitoring systems.

- The unit uses advanced signal filtering and vector analysis.

- It delivers stable data in harsh industrial environments.

Configuration Breakdown

- 3500/42-01-02

- 3500/42 monitor base

- A option 01

- 128229-01 internal termination I/O

- Supports Prox, Accel, and Velomitor sensors

- B option 02

- ATEX IECEx CSA approval

- Class 1 Zone 2 hazardous rating

- A option 01

- 3500/42 monitor base

Technical Data

- Brand: Bently Nevada

- Model: 3500/42-01-02

- Measurement range covers vibration and shaft position signals.

- Frequency response supports 1 Hz to 4000 Hz user settings.

- Sensitivity options reach 100 to 200 mV per mil.

- Velocity scaling supports multiple engineering ranges.

- Accuracy stays within ±1 percent full scale maximum.

- Resolution equals 0.3662 microampere per bit.

- Power use stays near 7.7 watts typical.

- Input impedance equals 10 kilo ohm.

- Recorder output provides 4 to 20 mA signals.

- Load resistance supports 0 to 600 ohm.

- Operating temperature suits standard rack environments.

- The unit resists electrical noise and signal interference.

- Short circuit protection protects all buffered outputs.

Installation Guide

- Mount the module inside a compatible rack slot.

- Connect sensors using shielded industrial cables.

- Verify correct scaling before system startup.

- Check LED status after power application.

- Keep signal cables away from power lines.

Commissioning and Maintenance

- The front panel allows quick signal verification.

- LED indicators simplify system diagnostics.

- Buffered outputs support external test tools.

- Routine inspection ensures stable operation.

- Firmware configuration stays user friendly.

Compatibility Notes

- The module works with standard rack infrastructure.

- It supports common industrial vibration sensors.

- It integrates with machine protection systems.

- It fits turbine and rotating equipment packages.

Certifications

- ATEX certified for hazardous areas.

- IECEx compliance supports global deployment.

- CSA approval ensures industrial safety.

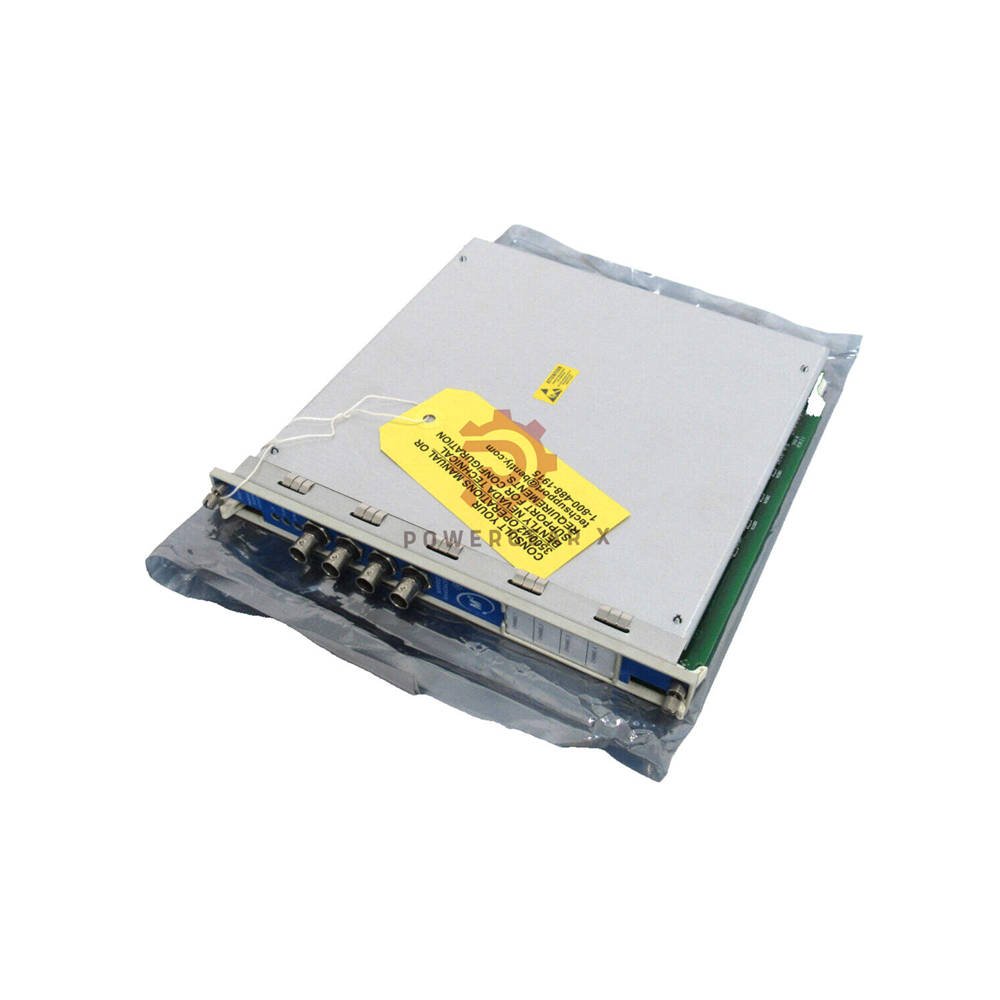

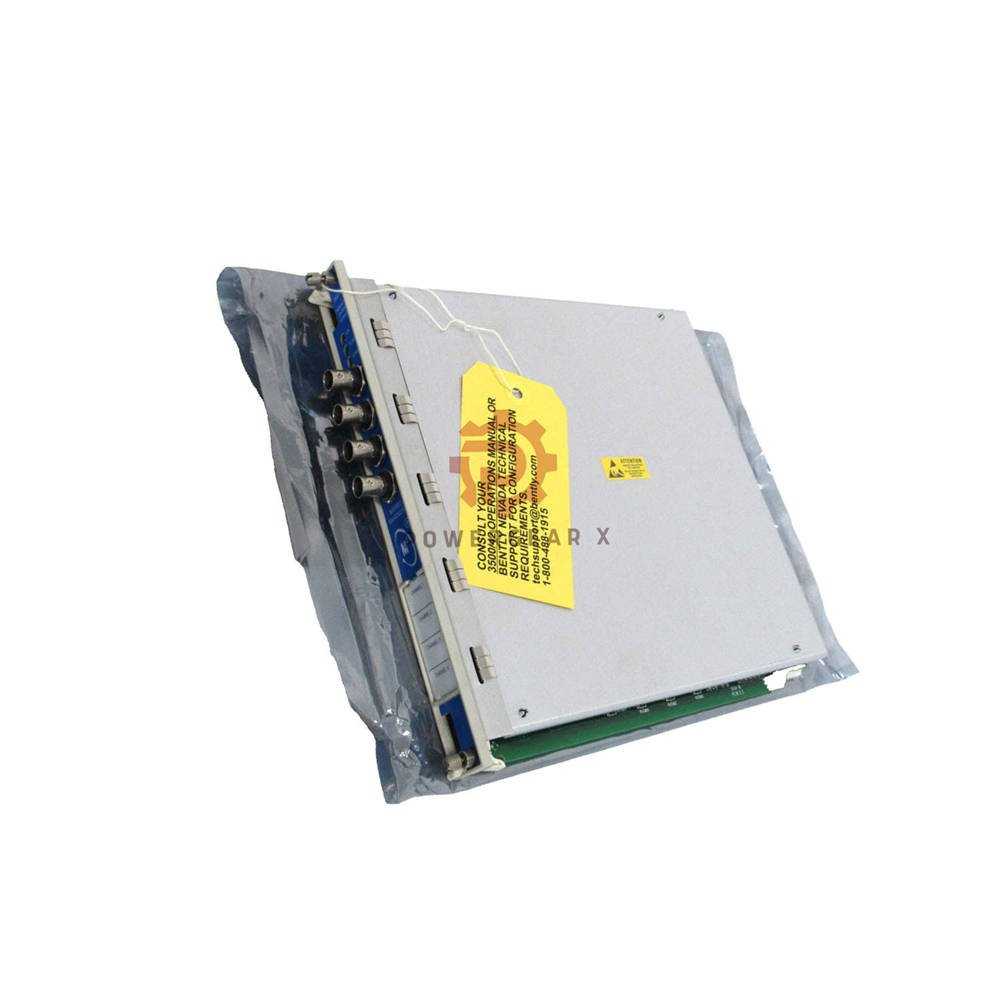

Package Contents and Warranty

- One monitor module unit.

- Protective industrial packaging.

- Quality inspection documentation.

- 12 month warranty included.

- Shipping available via FedEx UPS or DHL.

Typical Applications and Diagnostics

- Steam and gas turbine protection systems.

- Compressor vibration supervision.

- Pump condition monitoring.

- Early detection of shaft faults.

- Continuous machine health diagnostics.

Professional FAQ

- How do I select the right sensor type?

Match the sensor output with the monitor input range. Check plant standards first.

- What improves signal accuracy during installation?

Use short shielded cables. Ground the system correctly.

- Can this unit run in hazardous zones?

Yes. It carries certified approvals for Zone 2 areas.

- What should I inspect during routine service?

Check connectors LEDs and cable condition.

- How do I choose a supplier?

Select vendors with warranty support and fast logistics.

Contact Information

- Email: sales@powergearx.com

- WhatsApp: +86 18030005825

Copyright © 2026 Powergear X Automation Limited. All rights reserved.

Original Source: https://www.powergearx.com/

Partner: PLCDCS HUB Limited

There are no reviews yet.