Product details

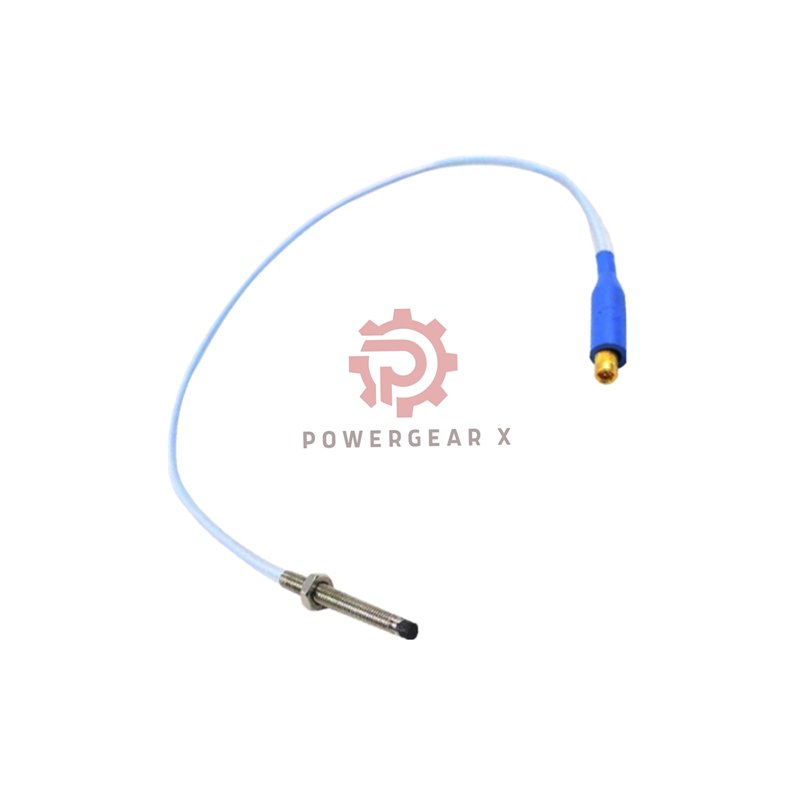

Product Overview: High-Performance Vibration & Displacement Measurement

Precision Bently Nevada 3300 NSv Proximity Probes are essential for industrial machinery monitoring. They accurately measure vibration and position of rotating shafts. This ensures early fault detection and prevents unexpected downtime. The model 330901-00-90-05-02-05 offers robust performance in demanding environments. Its design supports predictive maintenance programs effectively.

Detailed Technical Specifications

- Brand & Model: Bently Nevada 3300 NSv (330901-00-90-05-02-05)

- Measurement Principle: Eddy current displacement sensing.

- Electrical Specifications:

- Output Signal: Analog gap voltage.

- Cable Impedance: 75 Ω coaxial.

- Probe Resistance (0.5m): 4.0 Ω ± 0.5 Ω.

- Physical Construction:

- Case Material: Durable AISI304 stainless steel.

- Tip Material: Wear-resistant Polyphenylene sulfide (PPS).

- Thread: 1/4-28 UNF.

- Unthreaded Length: 0.0 inches.

- Overall Length: 9.0 inches (0.5 meter cable).

- Environmental Ratings:

- Operating Temperature: -52°C to +177°C (-62°F to +351°F).

- Storage Temperature: -52°C to +177°C.

- Note: Avoid sustained temperatures below -34°C to protect seals.

- Pressure Seal: Viton O-ring design (not factory pressure tested).

- Connector: Miniature coaxial ClickLoc (standard).

- Agency Approvals: Multiple international certifications for hazardous areas (EPL Ga, Gc, Dc).

- Weight: Approximately 14 to 150 grams.

Installation & Maintenance Guide

- Mounting Torque:

- Maximum: 33.9 N•m (300 in•lb).

- Recommended: 11.3 N•m (100 in•lb).

- First Three Threads Max: 22.6 N•m (200 in•lb).

- Thread Engagement: Do not exceed 0.563 inches for 3/8-24 threads.

- Debugging & Calibration: Use with compatible Bently Nevada monitors. System calibration is required for accurate gap-to-voltage conversion.

- Maintenance: Inspect probe tip and cable regularly for damage. Ensure connectors are clean and secure.

Compatibility & Integration

This probe connects seamlessly with Bently Nevada’s 3300 NSv monitoring systems. It uses the standard Miniature ClickLoc connector. It is a direct replacement for many legacy 3300 series probes. Always verify system compatibility before installation.

Certifications & Quality Assurance

The product carries multiple agency approvals for global use. It meets stringent industrial safety and performance standards. This includes certifications for hazardous locations.

Package Contents & Warranty

- One Bently Nevada 3300 NSv Proximity Probe.

- Standard documentation.

- Warranty: Full 12-month warranty against manufacturing defects.

- Shipping: We ship worldwide via FedEx, UPS, and DHL for reliable delivery.

Typical Applications & Diagnostic Power

- Continuous monitoring of turbo-machinery shafts (turbines, compressors).

- Vibration and axial position measurement in pumps and motors.

- Key Phase (speed) reference for timing analysis.

- Diagnostic Capability: Enables detection of:

- Unbalance, misalignment, and bent shafts.

- Oil whirl/whip instabilities.

- Rubbing and sleeve bearing wear.

Frequently Asked Questions (FAQ)

Product & Selection

- What makes this probe different from standard versions?

- This variant includes multiple hazardous area approvals (Option 05), making it suitable for more regulated plant environments.

- How do I choose the right cable length?

- Select based on the distance from the probe mounting point to the monitor. Standard lengths are 0.5, 1, 5, and 7 meters. Avoid excessive cable coiling.

- Can I use this with a non-Bently Nevada system?

- While electrically possible, optimal performance and accuracy are guaranteed only with compatible Bently Nevada driver/monitor units.

Installation & Experience

- Why is mounting torque so critical?

- Overtightening can damage the probe case or threads. Undertightening may lead to poor seating and unreliable signals. Use a calibrated torque wrench.

- The signal is noisy. What should I check first?

- Inspect the cable route. Keep it away from power lines and motor drives. Check connector integrity and ensure the probe tip is clean and free of debris.

- What is a common installation mistake to avoid?

- Exceeding the thread engagement limit. This can cause the probe tip to contact the shaft, resulting in immediate failure.

How to Choose the Right Probe (Buying Guide)

- Verify Your System: Confirm you need a 3300 NSv compatible probe with a 1/4-28 UNF thread.

- Check the Environment: For very cold settings (below -34°C), consider the seal limitation and plan accordingly.

- Select Cable Length: Measure the needed run from probe to junction box/monitor. Choose the next standard length up.

- Confirm Approvals: If your site requires specific hazardous area certifications, ensure Option 05 is selected.

- Consider Accessories: You may need extension cables, connectors, or a calibration kit for the full installation.

Need help with your selection or have technical questions? Contact our experts for support.

Email: sales@powergearx.com

Phone/WhatsApp: +86 18030005825

Copyright © 2025 Powergear X Automation Limited. All rights reserved.

Original Source: https://www.powergearx.com/

Partner: PLCDCS HUB Limited

There are no reviews yet.