Product details

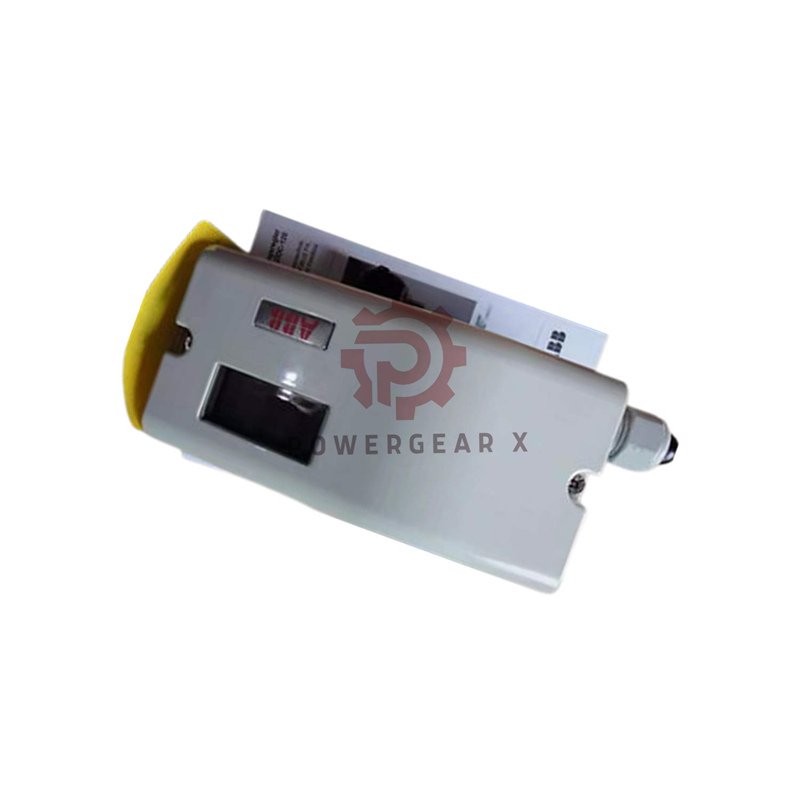

Product Overview: ABB V18345-1021120001 TZIDC

ABB V18345-1021120001 TZIDC valve positioner. Compact build. Stable output. Simple setup. Supports 4-20mA and HART. Designed for process plants needing reliable control.

Model Breakdown (Tree Structure)

V18345-1021120001 ├─ V18345 : TZIDC Intelligent Positioner ├─ 10 : Aluminum IP65 / NEMA 4X Case ├─ 2 : 4-20mA + HART (LKS adapter + FSK module) ├─ 1 : FM/CSA Explosion Protection ├─ 1 : Double Acting / Fail Freeze Output ├─ 2 : Electrical 1/2-14 NPT; Air 1/4-18 NPT ├─ 0 : No Analog Feedback ├─ 00 : No Mechanical Feedback └─ 1 : Standard Design

Key Specifications

- Power signal: 4-20mA HART communication

- Fail-safe action: Double acting / fail freeze

- Protection class: IP65 / NEMA 4X

- Ambient use: -40°C to +85°C operation

- Humidity: 95% operational, condensation allowed

- Terminal capacity: Up to 2.5 mm² analog signal lines

- Cable entry: 1/2-14 NPT or M20x1.5

- Pneumatic port: G 1/4 or 1/4-18 NPT

- Surface coating: Epoxy resin varnish, black RAL 9005

- Mounting: Linear or rotary actuators supported

Additional Technical Values

- Max air supply pressure: 6 bar nominal

- Signal accuracy: ±0.5% FS typical

- Stroke capability: 6-200 mm (application dependent)

- Response time: ≤ 0.3s typical with tuned parameters

- Control algorithm: Digital PID auto-tuning core

Logistics & Warranty

- Warranty: 12 Months standard replacement coverage

- Express shipping: FedEx / UPS / DHL

- Condition: Fully tested, cleaned, and sealed before dispatch

Contact & Sales Support

Frequently Asked Questions

Q1: How does this unit handle signal noise?

A: The internal digital filter reduces field interference. Users often tune damping for better valve response.

Q2: Can it be mounted on older actuator frames?

A: Yes. Many maintenance teams adapt via bracket kits. Previous site retrofits show quick alignment and stable seating.

Q3: Does the fail freeze action work in fast trip events?

A: Yes. The output holds position. Plants using compressor or boiler loops report stable freeze during air failures.

Q4: Can parameters be changed without full shutdown?

A: In many cases yes. Field engineers often adjust trim, range, and stroke live when safety permits.

Q5: Recommended supply pressure for stable control?

A: Many users run 4.5-5.5 bar for smoother final element motion. Results vary by valve load and media conditions.

Request specs or drawings via email.

**Copyright © 2025 Powergear X Automation Limited. All rights reserved.**

Original Source: https://www.powergearx.com/

Partner: Ubest Automation Limited

There are no reviews yet.