Unleashing the Titan: Why the PowerFlex 700H is Essential for Industrial Automation

Engineered for the Extremes: The VFD That Never Quits

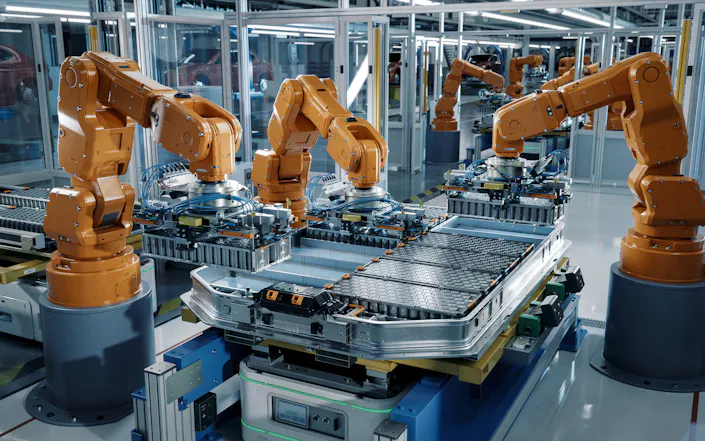

Imagine a demanding industrial environment. Heavy machinery operates with unrelenting force. Temperatures fluctuate from scorching to freezing extremes. Precision is not optional; it is strictly mandatory. In these harsh industrial automation landscapes, most equipment fails under the stress. However, the PowerFlex 700H series from Rockwell Automation stands apart. This is more than a Variable Frequency Drive (VFD). It is a powerhouse explicitly engineered for these unforgiving conditions. It delivers unmatched performance, flexibility, and control systems mastery. Whether managing colossal motors in a remote steel mill or fine-tuning a sterile pharmaceutical process, the 700H is relentless and reliable. Let’s delve into what makes this VFD a genuine game-changer in factory automation.

Dominating Power Capacity Across All Voltages

The PowerFlex 700H is built for performance and dominance, not for small tasks. Its robust power ratings offer an impressive and versatile operating range. This makes it a workhorse for almost any industrial application.

| Voltage | Power Range |

|---|---|

| 480V AC | 200–1900 HP |

| 600V AC | 150–2400 HP |

| 690V AC | 160–2000 kW |

This broad spectrum allows the 700H to handle immense factory equipment. Consider conveyor systems moving tons of raw materials across a quarry. It also precisely powers high-stakes processes like advanced robotic assembly lines. The goal is not just raw horsepower. It is about delivering that significant power with absolute finesse and stability. The series scales easily, offering robust solutions for both the largest industrial giants and the most delicate operations.

The Intuitive Command Center: Human Interface Module (HIM)

Operators step directly into the driver’s seat with the PowerFlex 700H’s Human Interface Module (HIM). This control panel is both highly intuitive and extremely powerful. Picture a clear, 7-line, 21-character LCD screen. It offers multilingual clarity in English, Spanish, German, and French, among others. The HIM is your essential gateway to total operational command. The calculator-style keypad feels familiar instantly. Shortcut buttons significantly streamline navigation through various menus and complex settings. Dedicated keys allow operators to adjust motor speed or issue a Start/Stop command immediately. This prevents fumbling and eliminates critical delays. For engineers and operators, the HIM transforms complex PLC programming into a straightforward, almost conversational experience.

Dual Control Modes for Maximum Application Flexibility

Flexibility is a defining characteristic of the PowerFlex 700H. Its dual operational control modes strongly prove this adaptability.

Sensorless Vector Control: This mode offers superior precision without requiring extra encoder hardware. It optimizes torque and speed delivery for dynamic applications. It maintains tight control, even when under widely varying loads.

Volts-per-Hertz (V/Hz): This is the proven choice for simpler mechanical setups. It provides reliable and consistent performance for standard motor applications where full vector control is unnecessary.

This intelligent adaptability means the 700H excels across diverse motor types and challenging operating conditions. It adjusts to your specific requirements, whether running a high-performance pump system or a basic fan array. This rare combination balances sophistication with straightforward simplicity. It guarantees peak performance, regardless of the unique application.

Field-Ready Design for Simplified Maintenance and Integration

The PowerFlex 700H is designed to enhance performance and simplify real-world field operations. Its practical features directly address common industrial challenges.

✅ Detachable Control Unit: This unit is the VFD’s “brain,” and it can be removed easily without disturbing the main power hardware. Swapping it for repairs or upgrades is faster, safer, and less disruptive to production schedules.

✅ Optional I/O Modules: Users can tailor the setup precisely with 24V DC or 115V AC inputs/outputs. This provides the freedom to match your current plant infrastructure perfectly.

✅ Seamless Network Integration: Internal communication kits integrate effortlessly with major control systems networks. These include Ethernet/IP, Profibus, DeviceNet, and ControlNet. Data flows quickly between the 700H and your wider ecosystem.

✅ Simplified Wiring: Pull-apart terminal blocks significantly improve connectivity. I/O cables can be plugged in or disconnected in mere seconds. This provides a secure fit every time, without tools or fuss.

These features are more than conveniences; they significantly reduce costly downtime. Efficiency dramatically increases, and the maintenance team spends less time wrestling with hardware. Instead, they focus on driving tangible operational results.

Author Commentary: Powergear X Automation Perspective

From our experience at Powergear X Automation, the modular architecture of the 700H series is its most significant advantage. In the B2B world, component commonality is gold. Sharing parts with its sibling, the PowerFlex 700S, drastically simplifies maintenance. It also reduces the need for sprawling, complex spare parts inventories. This shared platform approach saves facilities significant capital and warehousing space. The fact that larger models (frame-10 and up) are pre-housed in standard cabinets further streamlines large-scale deployment. According to a recent Statista report, downtime costs the manufacturing industry billions annually; features like the detachable control unit directly mitigate this risk.

You can explore robust automation solutions and VFD integration guides by visiting our official site: Powergear X Automation.

Toughness Defined: Endurance in Any Operating Environment

The PowerFlex 700H is not merely tolerant of the elements; it is specifically built to endure them.

Altitude: It performs at full power capacity up to 1000 m (3300 ft) above sea level. Derating options are available for specialized higher elevations.

Temperature Range: The drive operates reliably in a wide temperature band (specifics vary). Crucially, it stores reliably from -40℃ to 60℃ (40℉ to 140℉). It maintains function in frigid warehouses and super-heated foundries.

Durability Standards: It resists 1 G vibration and 15 G} shocks. It also handles humidity levels from 5% to 95% (in non-corrosive, non-condensing settings).

The drive is protected by your choice of IP21/UL Type-1 or IP54/UL Type-12 enclosures. This meets stringent NEMA standards. Furthermore, a built-in line reactor provides vital protection against power surges and harmful harmonics. This ensures longevity, even in electrically noisy settings.

Real-World Application Spotlight: Mining and Materials Handling

Consider a massive mining operation—a perfect test case for the 700H. The VFD must manage colossal material handling conveyors. The drive specified for such a task might be a model like the 20CD590B0ANNBNA0.

Key Specs: 480 V AC, 500 HP (Standard-Duty), 590 A, IP21 enclosure.

Why It Excels: This model is the heavy-duty option, built for brutal conditions and punishing loads. In mining, it delivers unwavering power and torque stability when process stakes are the highest. Its capability to handle fluctuating power quality is non-negotiable for remote sites. The 700H provides essential control for consistent throughput, minimizing jamming and wear.

Frequently Asked Questions (FAQ)

Q1: How does the PowerFlex 700H improve our total operational efficiency (OEE)?

The key improvement comes through reducing unscheduled downtime. Its built-in diagnostic tools quickly pinpoint faults. The modular, field-replaceable components, like the control unit, allow for incredibly fast Mean Time To Repair (MTTR). This translates directly into higher uptime, which boosts your overall equipment effectiveness (OEE).

Q2: We are currently using a different VFD brand. Is the 700H complex to integrate with our existing DCS/PLC platform?

The 700H is explicitly designed for seamless integration. Its optional internal communication kits (for Ethernet/IP, ControlNet, etc.) eliminate the need for cumbersome external gateway devices. If your plant uses Rockwell’s Logix platform, integration is virtually plug-and-play. It uses a single programming environment, making setup much faster than coordinating between disparate third-party drives.

Q3: What critical advice would an experienced engineer give for maximizing the 700H’s lifespan in a corrosive environment?

The IP54/UL Type-12 enclosure option is a must-have for environments with moisture or dust. Beyond that, proper cooling is critical. Ensure the cabinet’s cooling fans and filters are checked monthly. Regular preventative maintenance on the cooling system prevents the internal electronics from overheating, which is the number one cause of long-term component failure in industrial electronics.

Leave a Comment

Your email address will not be published. Required fields are marked *