The Evolution of Control Systems: Beyond Simple Monitoring

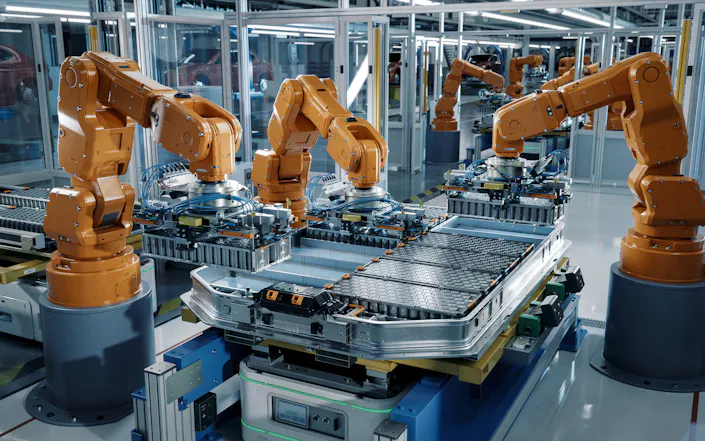

Factories no longer view Human-Machine Interfaces (HMIs) and Supervisory Control and Data Acquisition (SCADA) systems as mere display panels. They were once simple windows showing if a motor was running or a valve was closed. Today, these control systems operate as the nerve center of modern industrial facilities. Their function has shifted from basic data visualization to sophisticated analysis, prediction, and seamless integration across the enterprise. This transformation is driven by several powerful trends: the rise of Industrial IoT (IIoT), the adoption of hybrid-cloud technology, advanced analytics, and the crucial requirement for IT/OT convergence. At the core of this shift are new SCADA platforms and HMIs that are smarter, incredibly intuitive, and deeply embedded in daily operational decisions. Powergear X Automation supports this critical market evolution. We provide cutting-edge HMI panels and essential components from trusted industry leaders such as Allen-Bradley, Siemens, and Mitsubishi, empowering plants to sustain a competitive edge.

Leveraging IIoT for Real-Time Operational Visibility

The Industrial Internet of Things (IIoT) completely changes how operators interact with HMIs and SCADA. Systems now display much more than simple on/off status. They integrate massive sensor data streams from every machine across production lines. This provides real-time visibility into crucial metrics like overall performance, product quality, and critical energy consumption. For instance, pairing a robust Siemens Comfort Panel with an S7-1500 PLC allows operators to instantly visualize energy trends specific to each asset. This proactive insight helps managers eliminate inefficiencies long before they become expensive cost overruns. Furthermore, the Allen-Bradley PanelView family offers seamless connectivity with ControlLogix and CompactLogix PLCs, creating unified dashboards for all critical Key Performance Indicators (KPIs).

Hybrid-Cloud SCADA: The Best of Both Worlds

Historically, SCADA systems ran on local, on-premise servers. While reliable, this architecture severely limited scalability and secure remote access. Hybrid-cloud architectures provide an intelligent compromise: reliable local control paired with the inherent flexibility of the cloud. This design enables secure remote monitoring, much easier system scaling, and enhanced resilience against system failures. Plants can implement modernization in phases. They keep extremely latency-sensitive control functions on-premise while utilizing cloud services for global fleet dashboards, multi-site reporting, and secure data backups. Mitsubishi GOT2000 panels, for example, are perfectly suited for integration with secure remote-access tools, which extends operational visibility beyond the physical plant walls.

Proactive Maintenance Powered by Predictive Analytics

The future of SCADA is defined by being proactive, not reactive. Analytics models are now actively flagging subtle patterns that indicate an impending failure, moving beyond just waiting for an alarm to trip. This allows maintenance teams to plan necessary interventions long before a catastrophic breakdown forces production to stop. Consider a PanelView dashboard that displays subtle vibration trends on a critical motor. Connected advanced analytics can identify minor bearing wear several weeks in advance. This crucial heads-up enables perfectly planned downtime and efficient, smarter parts staging.

In the face of volatile supply chains and increasing budget pressures, adopting predictive maintenance is not merely an option—it is an absolute necessity for competitive operations.

Intuitive HMIs: Role-Based and Mobile-Optimized Design

The era of confusing, monochrome screens and overwhelming alarm notifications is ending. Modern HMIs prioritize clean, role-based views. These new interfaces emphasize superior usability and mobility. They ensure that operators can take action faster while minimizing the potential for human error.

High-performance options include the Allen-Bradley PanelView 5310 for tight, efficient integration with Logix controllers. Similarly, Siemens Comfort Panels offer highly customizable and flexible screen layouts suitable for diverse applications.

Cybersecurity as a Fundamental Design Requirement

As connectivity expands, so does the security risk landscape. Today’s HMI/SCADA platforms must incorporate security-first features. These features include robust encrypted communications, strict role-based access controls, multi-factor authentication, and sophisticated anomaly detection tools. The primary goal is always to protect operational uptime.

Furthermore, engineering environments from all major vendors now centralize security settings. This approach significantly reduces the risk of “configuration drift.” As we move deeper into Industry 4.0, security is no longer an optional add-on; it is an integrated design principle.

IT/OT Convergence: A Unified Operational Strategy

The rigid division between Operational Technology (OT) and Information Technology (IT) is rapidly disappearing. Modern SCADA and HMI platforms must natively connect with higher-level business systems. This integration allows leaders to align real-time production status with critical supply chain, quality, and financial data.

The crucial practical takeaway: Select HMIs and controllers that use communication standards compatible with your existing business systems. Plan your network and security architectures with IT/OT convergence as the central objective.

Conclusion: Building a Resilient Future with Smart SCADA

The current generation of industrial automation systems is shaped by powerful forces: deep IIoT integration, flexible hybrid-cloud deployments, sophisticated predictive analytics, highly modern interfaces, fundamental cybersecurity, and IT/OT convergence. These factors together are fundamentally redefining how today’s factories operate and compete globally.

Ready to accelerate your plant’s digital transformation?

Powergear X Automation can expertly assist you in evaluating your options, quickly sourcing in-stock panels, and ensuring fast shipment of components from top brands.

Click here to explore our wide range of HMI and SCADA solutions at Powergear X Automation and take the essential next step toward smarter, more resilient factory automation.

Application Scenario: Optimized Pump Station Monitoring

A municipality uses a Powergear X Automation solution to monitor remote water pump stations. Instead of sending technicians to check pumps weekly, a Siemens Comfort Panel acts as the local HMI, sending pump vibration and energy data via a secure, low-latency hybrid-cloud connection to a central SCADA system. The system uses a predictive model to alert maintenance 3-4 weeks before a pump bearing is expected to fail. This enables a shift from costly emergency repairs to scheduled, efficient component replacement during off-peak hours, dramatically reducing operational costs and unplanned downtime. This is a practical example of the Expertise and Experience we bring to real-world industrial challenges.

Frequently Asked Questions (FAQ)

Q1: How does a hybrid-cloud SCADA setup actually affect my system’s latency for critical control?

A: A well-designed hybrid-cloud architecture keeps critical, immediate control loops (like emergency stops or fast process regulation) entirely on the local PLC/DCS, guaranteeing low latency. The cloud component is used for non-critical, high-level functions like historical data aggregation, trend analysis, and remote reporting, where slightly higher latency is acceptable. The local network always retains core real-time control.

Q2: What is the single biggest operational benefit I can expect from upgrading to a modern HMI panel?

A: The most significant benefit is the reduction in human error and the increase in operator speed. Modern panels use intuitive, role-based graphics (high-resolution, customizable graphics) that reduce training time and eliminate screen clutter. This focused design means an operator can correctly identify a fault and initiate the correct response significantly faster than on an older, text-based system.

Q3: I have a mix of old and new PLCs (Allen-Bradley and Mitsubishi). Is IT/OT convergence possible without replacing everything?

A: Yes, convergence is definitely possible. It requires a strategic approach using modern middleware or specialized SCADA servers that can translate data across various industrial protocols (like Modbus, EtherNet/IP, PROFINET, etc.) and then structure that data into common IT-friendly formats (like OPC UA or MQTT). Focus on upgrading the communication gateway/SCADA layer first, rather than ripping and replacing every PLC or DCS component.